Top issue Science: MBene: Chemical exfoliation to obtain two-dimensional metal Mo4/3B2 vacancies

QQ Academic Group: 1092348845

Detailed

Beike Nano launches MBene series products, welcome to book.

0ne. Article overview

Extensive research has been invested in two-dimensional (2D) materials, usually synthesized by exfoliation of van der Waals solids. One exception is MXenes, which comes from the etching of constituent layers in transition metal carbides and nitrides. The article reports the experimental realization of a single-layer 2D molybdenum boride sheet with ordered metal vacancies, Mo4/3B2-xTz (where Tz is the end of fluorine, oxygen or hydroxide surface). Chemically ordered (Mo2/3Y1/3)2AlB2 and (Mo2/3So1/31/3)2AlB2 are produced by selective etching. The discovery of two-dimensional transition metal borides indicates that a wealth of two-dimensional materials can be obtained in the future through chemical peeling of laminate compounds.

Two, graphic guide

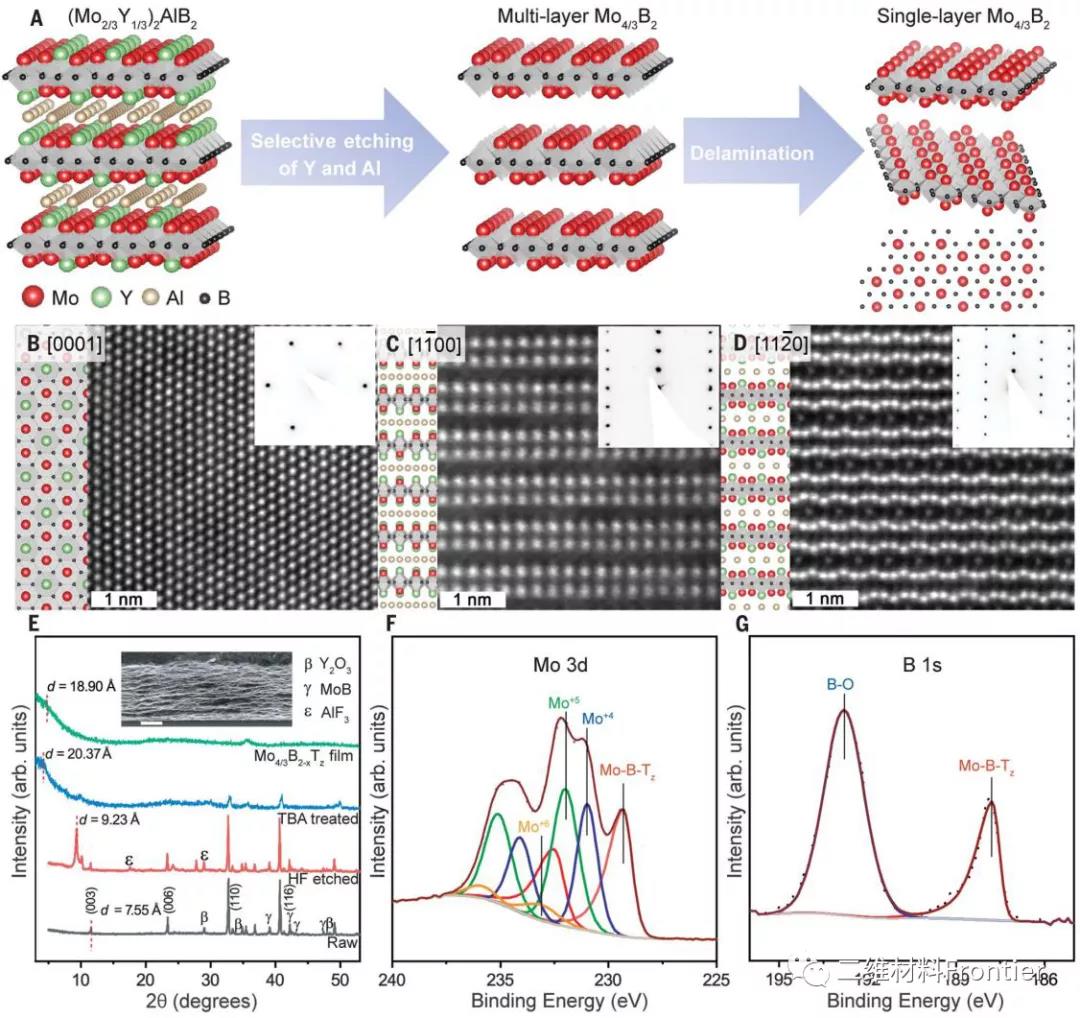

Figure 1.3 Synthesis and characterization of D(Mo2/3Y1/3)2AlB2 and its 2D derivative Mo4/3B2-xTz (borene).

(A) Schematic diagram of the conversion process of 3D i-MAB to 2D borene, before etching (left), after etching (middle), and after delamination (Mo2/3Y1/3) 2AlB2 (right). (Mo2/3Y1/3) The inner planes of Mo and Y in 2AlB2 are sorted, and ordered vacancies are generated after Y is removed after etching. (B to D) From the STEM image of [0001] (B), it can be seen that the in-plane chemical sequence of (Mo2/3Y1/3)2AlB2 i-MAB phase has the corresponding SAED mode. (B to D) STEM images along the axis of [0001](B), [1100](C), and [1120](D) show the in-plane chemical sequence of (Mo2/3Y1/3)2AlB2 i-MAB phase , The schematic diagram on the left of each image represents the arrangement of atoms in the space group R3m. (E) is the XRD pattern of (Mo2/3Y1/3)2AlB2 before and after (black) and after high-frequency etching (red), and after TBAOH insertion (blue) and delamination (green).

Figure 2. Structure characterization of single-layer borene (2D Mo4/3B2-xTz sheet).

(A and B) STEM images (A) of a single-layer Mo4/3B2-xTz sheet (dispersed on an amorphous carbon support), with corresponding FFT (insertion) and core loss EELS spectrum (B). (C) Higher magnification STEM image and simulated STEM image (inset) based on ideal (theoretical) drawings. (D) The top view of the ideal atomic structure of a single-layer Mo4/3B2 sheet from a theoretical simulation of the parent phase Mo, represented by red (top) and blue (bottom) atoms. (E and F) Side views of the ideal atomic structure of a single-layer sheet along the axis of the [1120](E) and [1100](F) regions. (G and H) If only the atoms of the first layer (L1) and the second layer (L2) are considered respectively, where L1 and L2 are shown in (L) and (F), it is the top view of the ideal atomic structure.

3. Full text summary

Two-dimensional borene nanosheets have been proved to be in the form of independent sheets larger than 50nm, which are chemically ordered from in-plane quaternary i-MAB phase (Mo2/3Y1/3) 2AlB2 compounds in a high-frequency solution. This is achieved by selectively etching Y and Al atoms. The borene formula is Mo4/3B2-xTz, and there are ordered vacancies on the metal sites. Compared with the mother phase, the flakes may be slightly defective, with x as high as ~0.5. The surface terminal Tz is identified as a mixture of O, OH and F, and the range of z is 2~3. The two-dimensional material can be selectively prepared in a multilayer form, such as a layered single-layer sheet in a colloidal suspension or as an additive-free filter membrane. The 2-dimensional Mo4/3B2-xTz tablets can be prepared by our top-down method to achieve high-concentration suspension, where the tablets are stable and can be processed in an aqueous environment. We also show that the same method can achieve the corresponding borene by selectively etching Al and Sc from the i-MAB phase (Mo2/3Sc1/3)2AlB2. Current and reference theoretical predictions show corresponding prospects, enriching the types of boride (or MBenes, also named corresponding prospects).

This information is sourced from the Internet for academic exchanges. If there is any infringement, please contact us and delete it immediately

- Previous: Lu Ligong/Gao Huile AF

- Next: A Rising 2D Star: Nove

Academic Frontier

Academic Frontier