Progress in the synthesis of MXene materials

First author: Wei Yi Corresponding author: Xu Bin Unit: Beijing University of Chemical Technology

Research Background

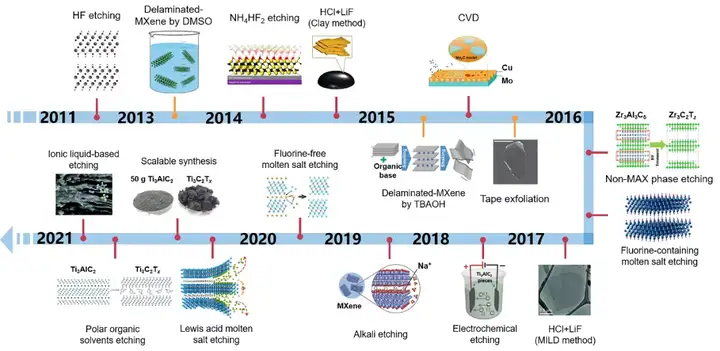

On August 22, 2011, Professor Yury Gogotsi and Professor Michel W. Barsoum of Drexel University in the United States reported on Advanced Materials for the first time a transition metal carbide Ti3C2Tx MXene with a two-dimensional layered structure. Because MXene has unique physical and chemical properties, such as metal-like conductivity, abundant surface functional groups, good flexibility and hydrophilicity, excellent mechanical strength, and structural diversity, it has been widely used by researchers in the past ten years. focus on. In terms of the types of MXene, i-MXene, solid solution MXene, etc. have come out one after another; in terms of etching methods, fluorine-containing etching, electrochemical etching, alkali etching, molten salt etching, etc. have successively realized the development of MXene. Preparation: In terms of application, the unique physical and chemical properties make MXene widely used in energy storage, sensing, catalysis, electromagnetic shielding, water treatment and other fields. The number of related papers has increased exponentially in recent years. With the continuous in-depth research of MXene materials, the application potential of MXene in various fields has gradually become prominent. In order to promote the further development of MXene materials, it is very important to systematically summarize the etching and stripping methods, large-scale preparation and anti-oxidation and stable storage strategies of MXene materials.

Article Introduction

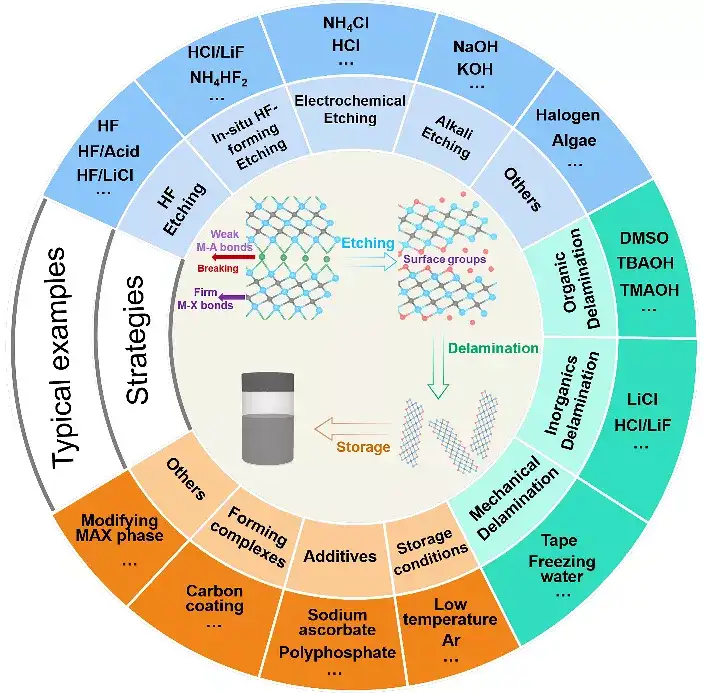

On the tenth anniversary of the advent of MXene materials, the team of Professor Bin Xu from Beijing University of Chemical Technology published a review titled Advances in the Synthesis of 2D MXenes in the internationally renowned comprehensive journal Advanced Materials on August 22, 2021. article.This review details the various etchings of MXenes (hydrofluoric acid etching method, in-situ formation of hydrofluoric acid etching method, electrochemical etching method, alkali etching method, molten salt etching method, and other methods) and The principle, development, product properties and influencing factors of the method of stripping (organic intercalation stripping, inorganic intercalation stripping, mechanical stripping), summarized the research progress in scale synthesis and oxidation resistance of MXenes materials at home and abroad, and looked forward to the future The direction of development.

Figure 1. MXenes etching, stripping, and stable storage strategies

Highlights of this article

Point 1: MXene etching methodBecause fluoride ions and aluminum have strong reactivity, using hydrofluoric acid as an etchant can achieve MAX etching and obtain multiple layers of MXene material. Due to the toxicity, corrosivity and environmental hazards of hydrofluoric acid, some mild and green synthesis methods have been reported one after another. The etching method of forming hydrofluoric acid in situ avoids the direct use of hydrofluoric acid, and the obtained multi-layer MXene can be dispersed into a single layer by gentle ultrasound or hand shaking. Alkali etching and electrochemical etching avoid the use of fluorine-containing substances. However, in the alkaline etching method, high concentration and high temperature are necessary conditions, while electrochemical etching has problems such as low yield and limited surface groups. In 2019, a new method of using Lewis acid molten salt as an etchant to achieve MAX phase etching at high temperatures appeared. This method not only avoids the introduction of -F group, but also has universal applicability, which greatly expands the etching range of MAX phase. More importantly, this method provides the possibility for researchers to further control the surface groups of MXenes, which is worthy of further study.

Point 2: How to peel off multi-layer MXeneThe etching of the precursor usually only obtains accordion-like multi-layer MXene, which needs to be further stripped to obtain two-dimensional MXene nanosheets. The peeling methods are mainly divided into organic intercalation peeling method, inorganic intercalation peeling method and mechanical peeling method. The principle of peeling is based on weakening the interlayer force of MXene nanosheets. Each stripping method is suitable for different MXene. For example, in the organic intercalation stripping method, DMSO intercalation agent can generally only be used for the stripping of Ti3C2Tx MXene, while TBAOH is generally suitable for the MXene obtained by the aqueous etching method. The MXene obtained by the etching method has only been reported to be peeled off by n-butyl lithium intercalation. The review summarized the principles, characteristics and scope of application of various stripping methods.

Figure 2. Development timeline of MXenes etching and stripping strategies

Point three: scale preparation of MXeneThe realization of large-scale production is the key to promoting the practical application of MXene materials. Ensuring the consistency of the morphology and physicochemical properties of MXene nanosheets is the main challenge in scale-up preparation. It is necessary to consider the problem of incomplete etching or partial over-etching caused by the temperature gradient generated in the reaction process of the large-sized reaction vessel. At the same time, it is also necessary to consider the corrosion of the used etchant on the equipment and the impact on the environment. Flexible MXene film, MXene fiber, etc. have important applications in the fields of flexible electronic devices and wearable devices, so their large-scale production is also the direction of future development.

Key point 4: Antioxidant strategy and stable storage method of MXene nanosheetsThe easy oxidation of MXenes in water and oxygen environment is one of the main factors restricting its practical application. This article summarizes the oxidation mechanism of MXenes. The oxidation of MXenes is always triggered by the edge and then diffuses to the surface. Therefore, adding antioxidants to protect the edges of MXenes is a common antioxidant strategy. In addition, changing the storage environment and changing the properties of precursors are also effective methods to delay the oxidation rate of MXenes.

Advances in the Synthesis of 2D MXeneshttps://onlinelibrary.wiley.com/doi/10.1002/adma.202103148

Corresponding author introduction

Professor Xu Bin. Professor and PhD supervisor of the School of Materials Science and Engineering and the State Key Laboratory of Organic-Inorganic Composite Materials, Beijing University of Chemical Technology, concurrently serves as deputy secretary-general of China Supercapacitor Industry Alliance and deputy director of Beijing Key Laboratory of Electrochemical Process and Technology of Materials. He graduated from Beijing Institute of Technology with a Ph.D. in 2006, and visited Drexel University in the United States as a state-sponsored senior research scholar in 2016-2017. Mainly engaged in the research and development of advanced chemical power and energy materials, including supercapacitors, lithium/sodium/potassium ion batteries, lithium-sulfur battery electrode materials and devices, electrochemical energy storage carbon materials and new two-dimensional MXene materials. As the project leader, he has successively undertaken sub-projects of the National Natural Science Foundation of China, National 863, National Key R&D Program, Beijing Science and Technology Plan, and enterprise horizontal projects. He has published more than 120 SCI papers in Adv Mater, Adv Energy Mater, Adv Funct Mater, ACS Energy Lett, Nano Energy and other journals, with more than 8,100 citations.

This information is sourced from the Internet for academic exchanges. If there is any infringement, please contact us to delete it immediately

Academic Frontier

Academic Frontier