ACS APPLIED MATERIALS INTERFACES: Tough multifunctional composite membrane actuator based on cellulose nanofibers for smart wearable devices

QQ Academic Group: 1092348845

Detailed

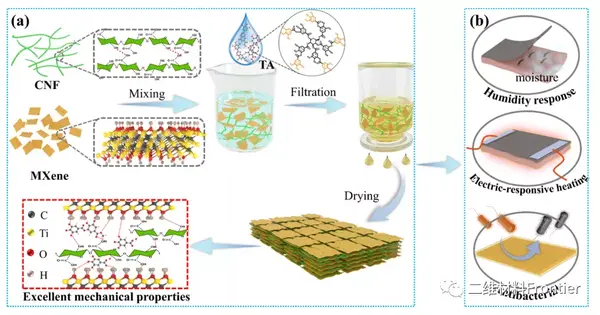

In the article, it is reported that a vacuum-assisted filtration method is integrated with Ti3C2Tx (MXene) and tannic acid (TA) to successfully construct a cellulose nanofiber (CNF)-based thin film driver that has high mechanical properties, Excellent Joule heating and antibacterial ability. Due to its unique nacrelike structure and strong hydrogen bonds, the tensile strength and toughness of the composite membrane reached 275.4 MPA and 10.2 MJ·m−3, respectively. Importantly, the hydrophilicity of CNF and the variable interlayer spacing of MXene nanosheets confer The sensitive humidity response and extraordinary stability of the composite membrane (1000 cycles). With the aid of MXene nanosheets and TA, the composite film not only has excellent Joule heating performance, but also has significant antibacterial properties against Gram-negative E. coli and Gram-positive Staphylococcus aureus. Benefiting from the above-mentioned advantages, the proof-of-concept smart clothing is assembled from prepared films, which can regulate humidity and temperature.

Two, graphic guide

As shown in Figure 1.

Figure 2 Characterization of CNF-MXene-TA composite membrane. The CNF-MXene-TA composite film obtained on the surface of Figure 2a is bright black and exhibits elasticity after being folded at 90°. The corresponding cross-sectional scanning electron microscope image shows a fairly orderly compact layered microstructure in the entire film, which is regular Layered structure. The result was attributed to the enhanced interfacial interaction between CNF and MXene, which originated from the introduction of active catechol groups. The magnified SEM image (Figure 2c) shows that MXene nanosheets are evenly distributed in the CNF matrix and stacked closely along the planar path, so that the composite film has high conductivity and excellent mechanical strength. XRD, FTIR and XPS to better verify the chemical structure and hydrogen bond interaction between CNF, MXene and TA. Figure 2 g-i shows that the nanostructure self-assembled by multiple hydrogen bonds, the CNF-MXene-TA composite film obtained exhibits excellent mechanical strength and toughness.

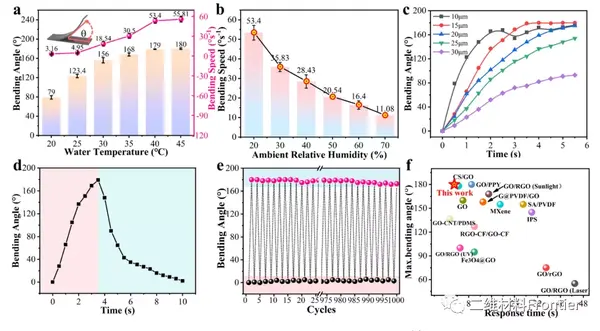

Figure 3. Humidity response performance of CNF-MXene-TA-II composite film actuator. As the water temperature increases from 20°C to 45°C, the maximum bending angle of CNF MXene TA-II composite tape increases from 79° to 180°, and the bending speed increases significantly. When the relative humidity of the environment increases from 20% to 70%, CNF The bending speed of the MXene TA II composite film strip is significantly reduced (Figure 3b). The thinner composite membrane (10μm) has a larger bending angle, but due to its lower stiffness, the bending stability is poor; the thicker composite membrane (30μm) has a smaller bending angle due to its high stiffness (Figure 3c) ). The ideal thickness of the composite film is 15 μm. Under high humidity gradient conditions (water temperature of 40°C and ambient relative humidity of 20%), the film undergoes a 180° bending angle within 3.5 s and almost returns to its original state after removing the humidity gradient. The entire curve straightening process takes about 10 seconds (Figure 3d). As shown in Figure 3e, this bending-no-bending process can be repeated more than 1000 times, which means external repeatability and good stability of the driving deformation. In addition, the composite thin-film actuator has an ultra-short driving time and bending amplitude, and its performance is better than that of humidity-responsive thin-film actuators reported in other documents.

Figure 4. Joule heating performance of composite film actuator. MXene nanosheets endow composite film actuators with good Joule heating performance due to their excellent electrical conductivity, and have great prospects in smart and wearable thermal management. Figure 4a shows that the average conductivity of CNF-MXene film increases significantly with the increase of MXene content, which is due to the continuous formation of highly efficient MXene conductive pathways in the CNF matrix. As shown in Figure 4b, the surface temperature of CNFMXene-TA-II composite membrane increased rapidly with time, and then reached an equilibrium value; under 5V input voltage, the surface temperature of CNF-MXene-TA-II composite membrane increased from 20 °C increased to 37.2°C, meeting the standard requirements of the human body. Since higher transfer current produces larger Joule heating, the steady-state saturation temperature difference increases significantly as the supply voltage increases. When the supply voltage is 12.5V, the temperature difference can exceed 72°C (Figure 4c). Figure 4d-e shows that the composite film has good heating durability and long-term stability.

3. Full text summary

The author successfully prepared a high-performance moisture-sensitive composite film driver through a simple vacuum-assisted self-assembly method. The driver is composed of cellulose nanofibers, MXene nanosheets and TA, and has excellent Joule heating and antibacterial capabilities. MXene nanosheets and TA molecules are uniformly combined in the CNF matrix to build a unique nacrelike structure. The strong hydrogen bond interaction between CNF, MXene and TA gives the composite film a high tensile strength of 275.4 MPA, a high fracture strain of 5.8%, and a toughness of 10.2 MJ·m−3, thereby satisfying the practical application of smart wearable devices. Some of the key requirements. Most importantly, due to the rapid absorption and desorption of CNF and the change of interlayer spacing induced by water gradient of MXene, the composite film has excellent humidity response performance, bending speed (53.4°/s) and ultra-high stability (1000 times) Cycle, no degradation). In addition, the composite film driver shows sufficient Joule heating efficiency under low voltage, which is healthy for human body and has a good bactericidal effect on Escherichia coli and Staphylococcus aureus. In view of all these characteristics, the composite film actuator is designed as a smart garment that can adjust the humidity and temperature of the human body. This research provides a new way to develop high-performance, multifunctional actuators for smart wearable devices. Article link: https://pubs.acs.org/doi/10.1021/acsami.1c09653.

Scan the QR code|Follow us 17715390137 (same number on WeChat)

This information is from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

- Previous: Angew: Nuclease-resist

- Next: A Rising 2D Star: Nove

Academic Frontier

Academic Frontier