MXenes hydrogel sensor performance reaches new limits

QQ Academic Group: 1092348845

Detailed

【Research Background】

Hydrogels are an interesting class of viscoelastic materials that consist of three-dimensional (3D) networks of hydrophilic polymers that are crosslinked chemically or physically, and have the ability to absorb and retain large amounts of water. Conductive hydrogels are a promising class of materials that can be used in applications such as wearable electronics, robotics, and prosthetics. These applications require sensors to be highly sensitive, scalable, and easy to adhere to any complex surface, such as human skin. However, electromechanical sensors based on hydrogels generally exhibit relatively low sensitivity, and as a viscoelastic material, their electromechanical response to external forces can transmit unstable noise, which can cause hysteresis and fluctuation. Therefore, effective approaches are needed to improve the above problems.

[Achievement Profile]

Recently, the research group of Professor Husam N. Alshareef of King Abdullah University of Science and Technology published a research paper titled: MXenes stretch hydrogel sensor performance to new limits in the internationally renowned academic journal Science advances. Ti3C2Tx) hydrogel composites outperform all reported strain sensor hydrogels. The obtained composite hydrogel [MXene-based hydrogel (M-hydrogel)] showed excellent tensile strain sensitivity, with a GF of 25, which is 10 times that of the original hydrogel. In addition, M-hydrogels show superior stretchability of more than 3400%, instantaneous self-healing ability, excellent compliance, and adhesion to various surfaces including human skin. M-hydrogel composites show higher sensitivity under compressive strain (GF = 80) than under tensile strain.

[Picture and text guide]

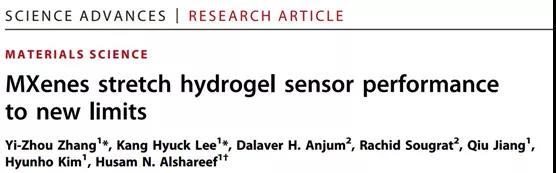

Figure 1. Characterization of M-hydrogel.

Figure 1. Characterization of M-hydrogel.

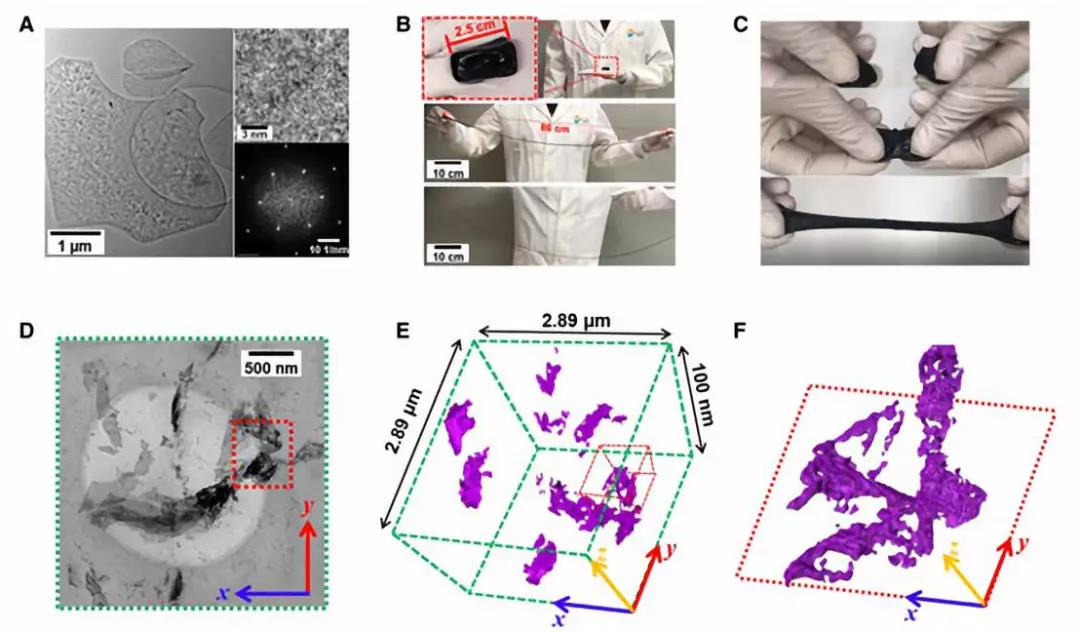

Figure 2. Electromechanical properties and mechanism of M-hydrogel composites.

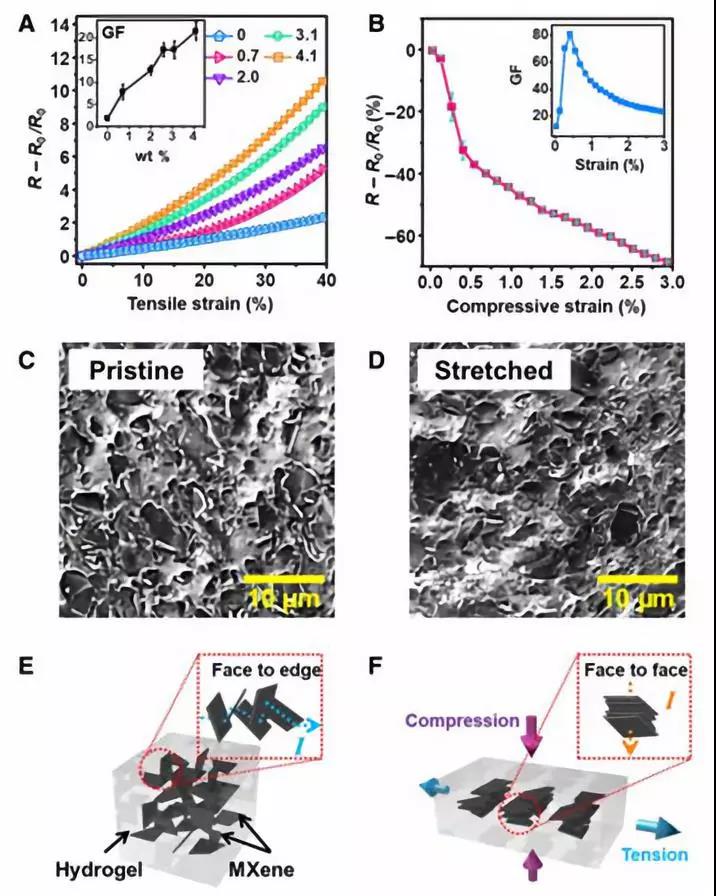

Figure 3. M-hydrogel‘s ability to perceive its surface motion.

Figure 3. M-hydrogel‘s ability to perceive its surface motion.

Figure 4. General sensing performance of M-hydrogels. (A to E) Respond to (A) finger flexion, (B) different gestures, (C) human pulse and (D and E) facial expressions resulting from changes in M hydrogel resistance.

Figure 4. General sensing performance of M-hydrogels. (A to E) Respond to (A) finger flexion, (B) different gestures, (C) human pulse and (D and E) facial expressions resulting from changes in M hydrogel resistance.

Figure 5. Advanced sensing applications for M-hydrogels. (A) Signature induction diagram. (B to D) Changes signed by (B) and (C and D) OK written by different volunteers. (E) Schematic diagram of sound induction. (F to H) The resistance responds to the letters "B", "D", and "E" that sound similar.

Figure 5. Advanced sensing applications for M-hydrogels. (A) Signature induction diagram. (B to D) Changes signed by (B) and (C and D) OK written by different volunteers. (E) Schematic diagram of sound induction. (F to H) The resistance responds to the letters "B", "D", and "E" that sound similar.

[Summary of this article]

In this paper, MXene (Ti3C2Tx) -based PVA hydrogel with excellent sensing function was developed. Adding MXene nanosheets with multiple surface functional groups to a PVA hydrogel can result in excellent stretchability and transient self-healing. The high sensitivity of MXene nanosheets, the anisotropic response of M-hydrogels to compressive strain and tensile strain, and the combination of its viscoelastic properties make the resulting composite hydrogel an interesting sensing material that can be conveniently used Detect the direction and speed of movement of its surface. Advanced sensing applications that involve small changes in motion speed and trajectory (such as handwriting, facial expressions, and sound signals) can detect with high accuracy and sensitivity.

Literature link:

http://advances.sciencemag.org/content/4/6/eaat0098

- Previous: MoS2 / MXene high-perf

- Next: Advanced Materials | A

mxene academic

mxene academic