Research Background

Due to the unique physical and chemical properties, MXene been widely studied , involving a plurality of field, MXene preparation are MXene base application, a large amount is related to the preparation MXene practical application , typically MXene release top-down approach, which peeling principle Decided the feasibility of large-scale preparation . Fewer layers MXene colloid , multi-layered MXene powder, a small layer of MXene powder MXene presence of the basic state, and perhaps imperfect place, but the efforts of researchers, which have achieved rapid mass production of , and all Applied for related patent protection. This time, we will introduce the mass preparation of MXene , especially the rapid mass preparation of few layers of powder .

Literature 1 : Large-scale preparation of few layers of M X ene colloid

Large-scale delamination of multi-layers transition metal carbides and carbonitrides “ MXene ”

Dalton Trans., 2015, 44, 9353–9358 .

brief introduction

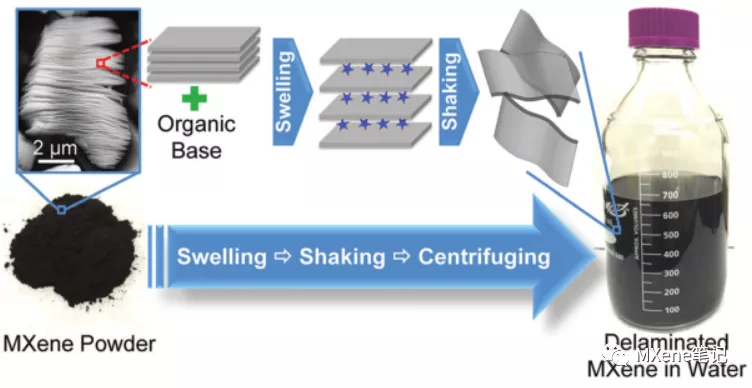

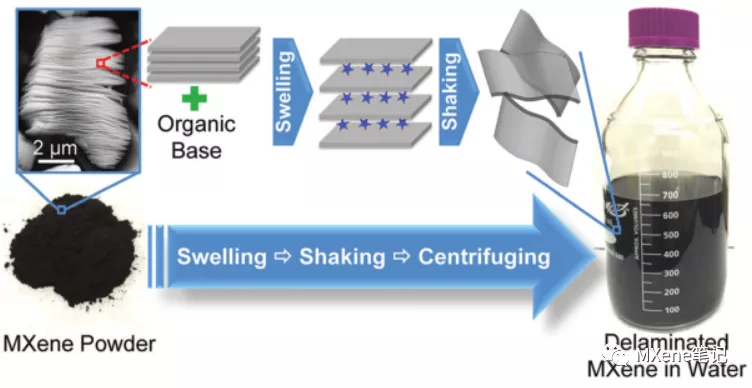

This paper reported that the organic base layer is interposed , through subsequent manual shaking, ultrasonic peeling way, a layer of less MXene large scale preparation of nanosheet, since the organic macromolecular material is used lye, i.e. T MAOH, of TBAOH the like, these large After the molecules are embedded in the multiple MXene layers, the interlayer distance is increased, and the interlayer force is weakened . After manual shaking or ultrasonic peeling of the instrument, a uniformly dispersed MXene nanosheet solution can be obtained . Filter, you can get a flexible self-supporting MXene film. Other organic bases , such as n-butylamine can be peeled V 2 CT X and of Ti . 3 the CNT X like MXene material. Unlike dimethyl sulfoxide intercalated release Ti . 3 C 2 T X , only Ti3 C 2 T x is valid . The preparation method of organic alkali intercalation - peeling can be applied to different MXene material systems. Due to the simple preparation method, coupled with the versatility of this method in peeling various MXenes , large-scale M X ene aqueous solution preparation.

Literature 2 : Large-scale preparation of multilayer M X ene powder

Scalable Synthesis of Ti 3 C 2 T x M X ene

Adv. Eng. Mater. 2020, 1901241 .

brief introduction

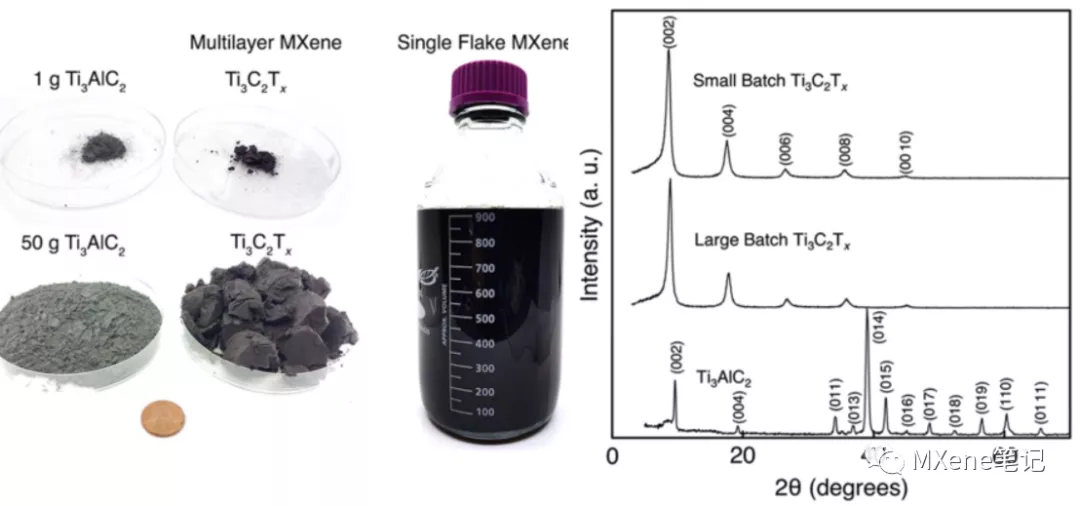

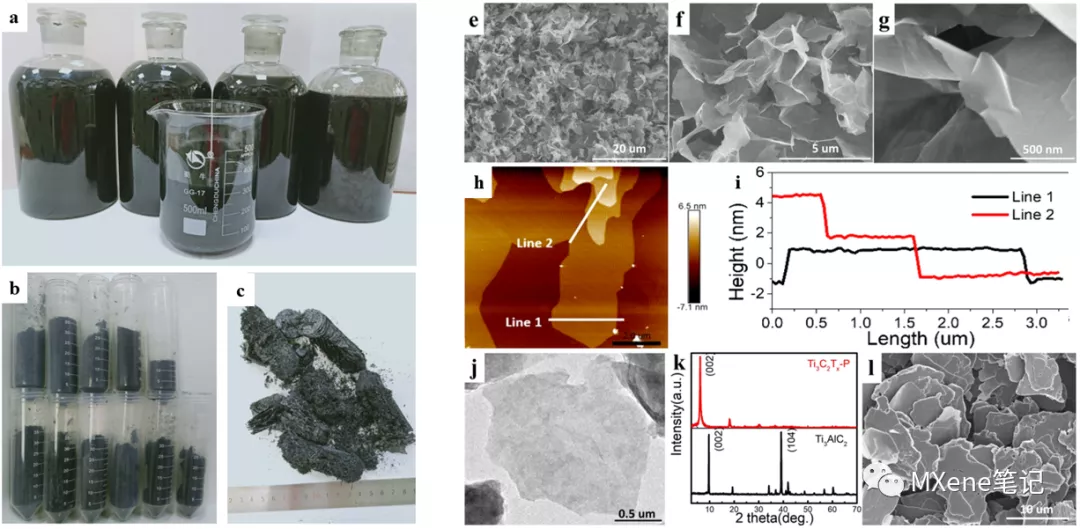

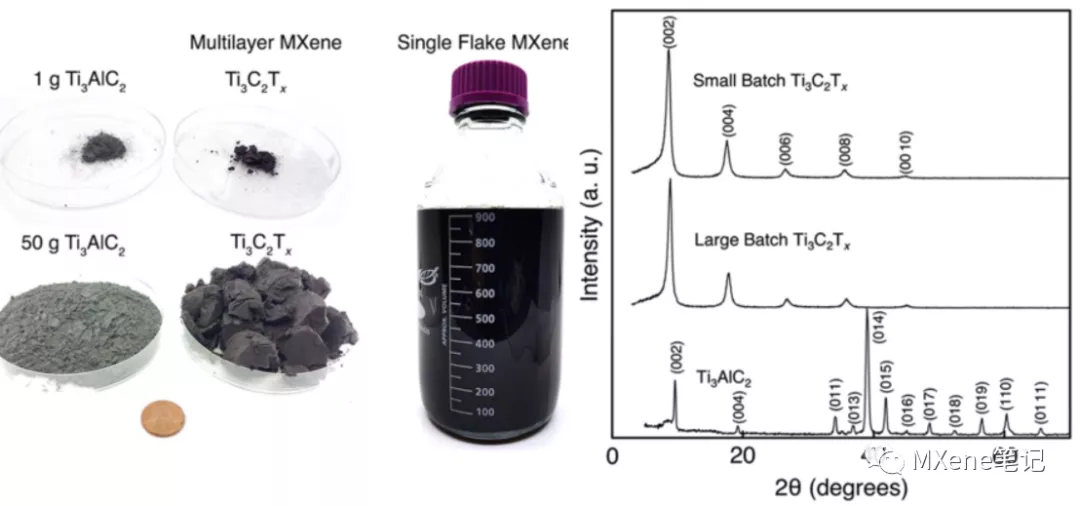

It is found in this paper that no matter whether a small amount of Ti 3 A l C 2 (1 g) is used for etching preparation , or a large amount of Ti 3 A l C 2 ( 50 g) is used for etching to prepare multiple layers of Ti 3 C 2 M X ene powder , preparation The characterization results of the obtained multilayer M X ene samples are basically the same, including the results of macro tests such as X RD , and the micro test characteristics such as S EM , which fully shows that Ti 3 A l C 2 M AX In addition to the use of larger reaction vessels and more etching solution , there is no detail requirement in other aspects. These results indicate that, according to similar principles, it is feasible to prepare MXene in large quantities for industrial application . Although the preparation of Ti 3 C 2 is taken as an example in this article , due to the similarity of M X ene , it is also effective for other MXene systems .

Literature 3 : Fast and large-scale preparation of a few layers of M X ene powder

Fast and Universal Solution-Phase Flocculation Strategy for Scalable Synthesis of Various Few-Layered MXene Powders

J. Phys. Chem. Lett. 2020, 11, 1247−1254 .

brief introduction

Although been achieved less layer MXene colloid , multilayer MXene powder large amount of preparation, and in the actual application process, in order to achieve better performance, more desirable is a material in a small layer state ( two -dimensional material layers less than 5 , specifically see reference . 1 - 2 ) , in addition, MXene nanosheet is easily oxidized in an aqueous solution degradation , prepared in M X- ENE material is preferably as small layer powder state , to facilitate the storage of anhydrous oxygen-free environment . By freeze-drying, the MXene solution can be lyophilized to a powder state, but the whole process is time-consuming and yieldsVery few , and there is agglomeration .

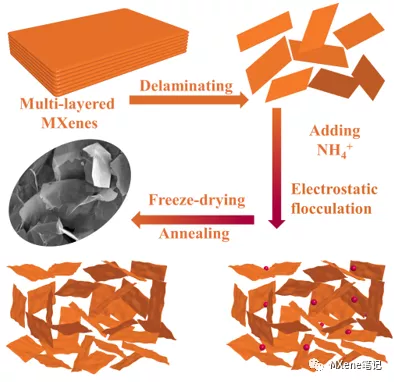

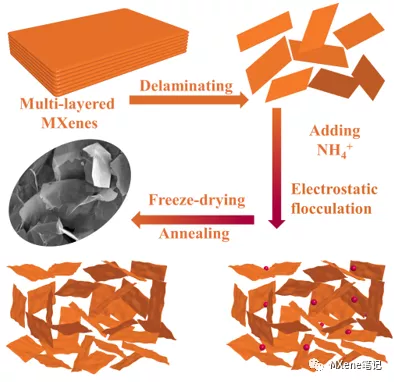

Han Weiqiang Zhejiang University research group from MXene starting basic properties ( surface electronegativity ) , systemic proposed liquid flocculated policy ( including ammonium ions method and an improved ammonium ion method , see ref . 3 - . 4 ) . Adding positively charged ammonium ions to it destroys the electrostatic equilibrium state of the M X ene solution . With the automatic electrostatic precipitation of MXene nanosheets , the upper layer of water is drained, which can greatly save the time of cooling and drying . The flocculent precipitate was lyophilized, and finally the rapid preparation of a few layers of M X ene powder was achieved ( no agglomeration under low-power scanning electron microscope ) .

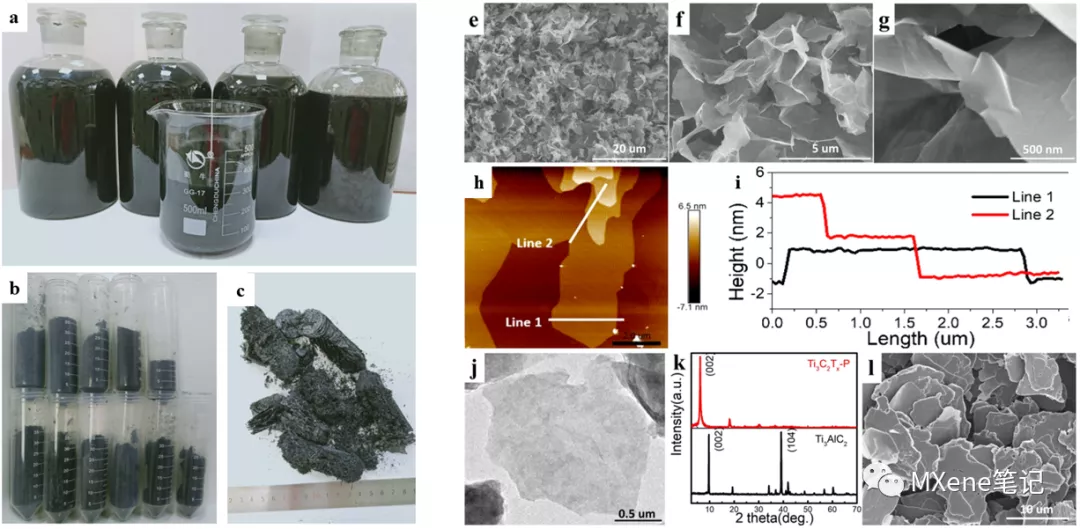

Liquid-phase flocculation - electrostatic sedimentation related physical map

Considering the original MAX phase particles of different sizes, different thickness, are etched multilayer M X- ENE exist where the size of substantially different sizes , M X- ENE ultrasound should not be peeled off across the board ( a uniform ultrasonic release time ) . This paper further proposed a method to gradually peeled , i.e. the peeling layer is less good M X- ENE nano- sheet promptly centrifuged collected, peeled not peeled ultrasound continued good ( after ultrasonic peeling, collected by centrifugation supernatant layer is less precipitate a multilayer , Add water to the precipitate and continue ultrasonic peeling, so repeated) , improve the yield of few layers of M X ene nanosheets , and avoid the generation of M X ene fragments . OF also be repeatedly peeled off, the precipitate after centrifugation were characterized and found that S the EM was rubble films like (Thick ) , X- the RD the current M X- ENE characteristic peaks were peeled off after precipitation repeated, not belonging to the multilayer peelable M X- ENE . In the subsequent electrostatic coagulation link, the centrifugal assisted method reduces the coagulation time and improves the preparation efficiency. As a result, an improved ammonium ion method ( including gradual peeling and centrifugal assisted sedimentation ) was formed , and finally a rapid mass production of a few layers of M X ene nanosheet powder was achieved . The whole preparation process is simple, all steps are scalable, or even all steps ( etching , peeling electrostatic coagulation , etc.) to put a large-scale without loss of M X- ENE nanosheet characteristics , great ofPractical application prospects .

Physical map and material characterization

Basic principle: the small layer of MXene nanosheets after stripping can exist stably in aqueous solution for a period of time ( the supernatant collected by centrifugation will not be oxidized in a short time ) , and the reason for the stable existence is that the surface of the nanosheets is negative electrostatic interaction between the nano-sheets are mutually exclusive, so that the M X- ENE does not occur agglomeration stacked in an aqueous solution, which is a considerable part of M X- ENE root cause start target application directly from an aqueous solution , if the addition of a positively charged with If the mass ( large volume and heavy mass ) is destroyed, the electrostatic equilibrium state is destroyed, and the automatic aggregation of M X ene nanosheets will occur . Among the positively charged groups, in view of the volatile ammonium salts, a subsequent segment can be removed by annealing, so choose the ammonium ion ( ammonia water, ammonium salts, such as the chemical nature of the unstable ammonium bicarbonate, easy to heat decomposition , heat At about 60 ℃, it decomposes into NH 3 21.5% and CO 2 55.7%, H 2 O 22.8% ) , in contrast, metal ions are difficult to remove in the powder state ( generally by washing to remove metal ions, and washing makes M X ene return to the solution state ) .

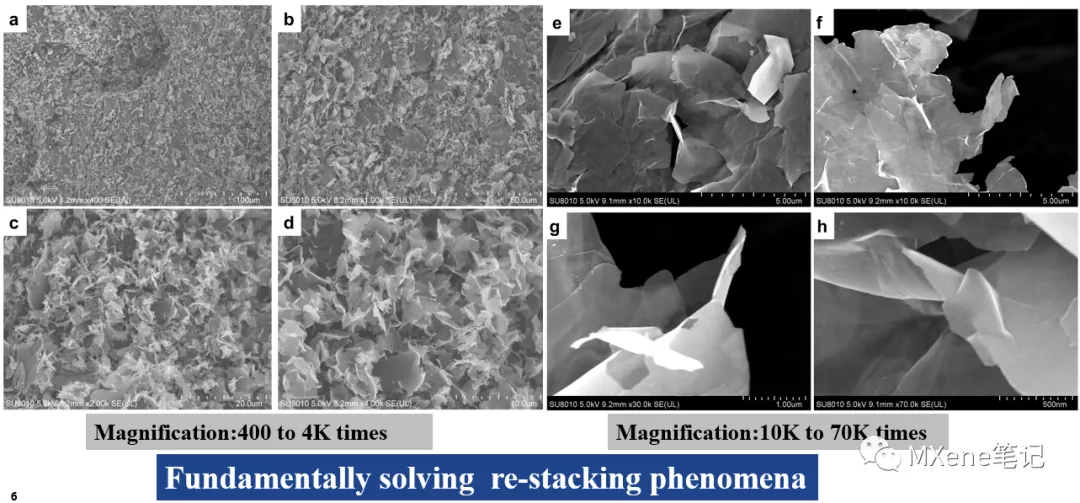

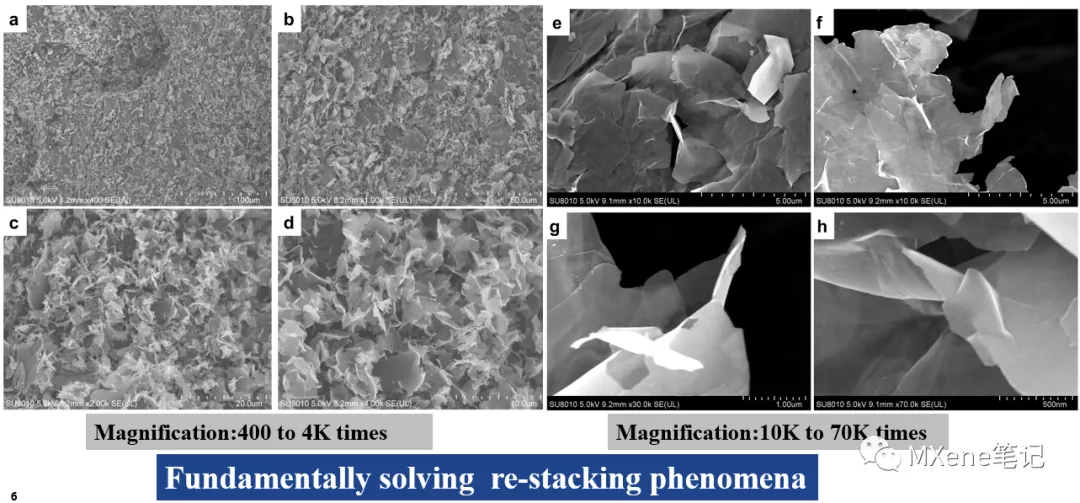

Material Characterization S the EM ( from . 4 00 times to . 7 0K)

The ammonium ion method and the improved ammonium ion method solve the problem of agglomeration of M X ene , and realize the rapid and large-scale preparation of a few layers of M X ene nanosheet powder , thereby avoiding the problem of easy oxidation of M X ene . Layer M X ene powder is stored in a water-free and oxygen-free environment, such as a glove box or sealed for storage , which is convenient for subsequent applications .

References :

[1] Ultrathin Two-Dimensional Nanomaterials. ACS Nano . 2015, 9, 9451−9469 .

[ 2] Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev.

2017, 117 (9), 6225−6331.

[ 3] Partial Atomic Tin Nanocomplex Pillared Few‑Layered Ti3C2Tx MXenes for Superior Lithium‑Ion Storage . Nano‑Micro Lett. (2020) 12:78 .

[ 4] Fast and Universal Solution-Phase Flocculation Strategy for Scalable Synthesis of Various Few-Layered MXene Powders . J. Phys. Chem. Lett. 2020, 11, 1247−1254

Related issues :

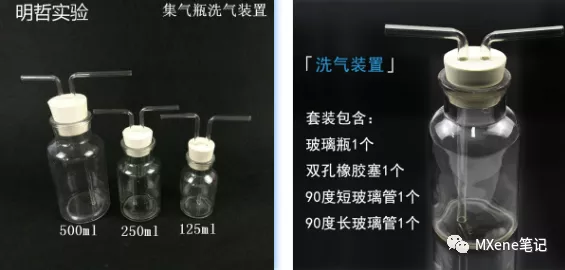

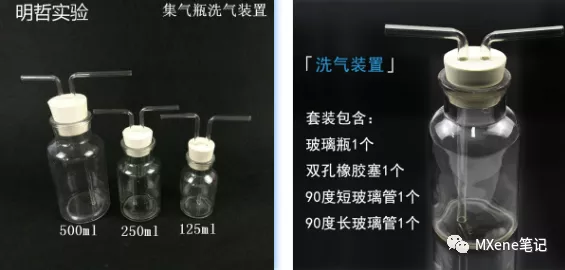

① How does MXene pass argon during ultrasound

Scouring the Po buy washing bottle, once it requires a plurality of through, latex catheter tube to the glass bottle together in series , can refer to FIG .