MXene breakthrough: Nanocomposites used to reduce friction and wear on rough steel surfaces

QQ Academic Group: 1092348845

Detailed

Abstract

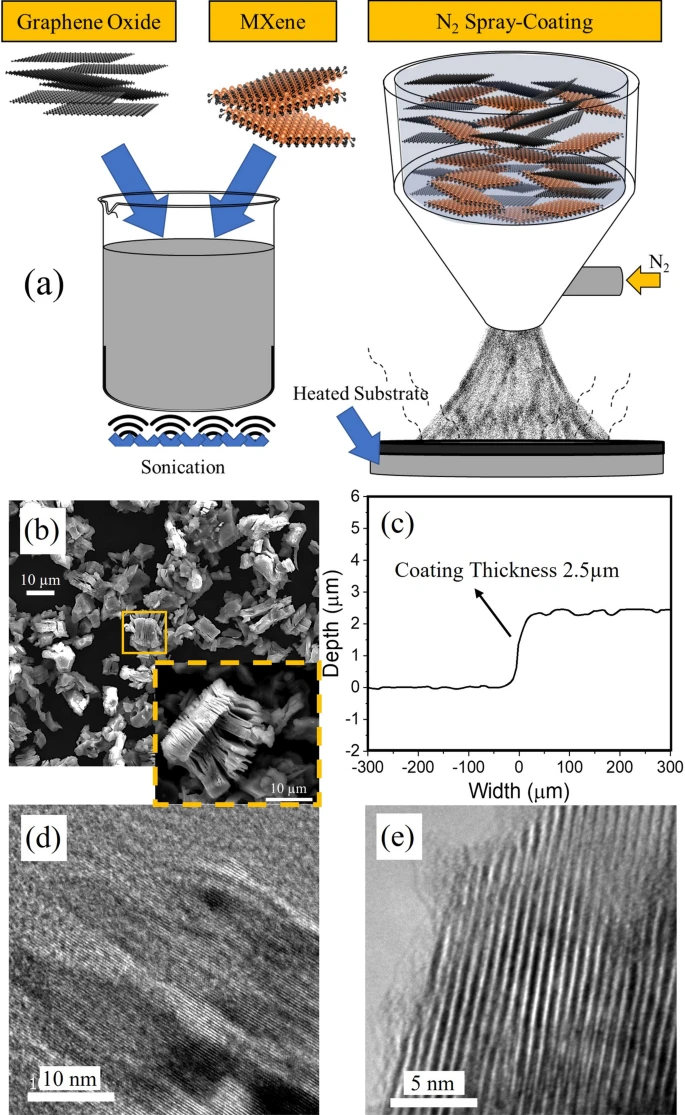

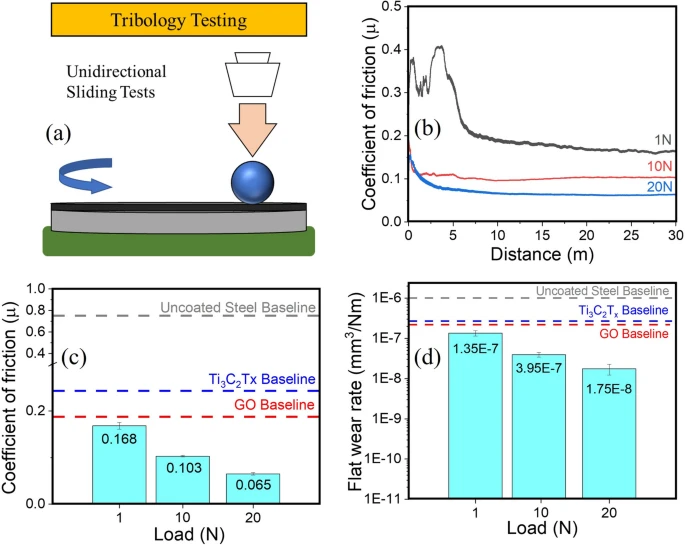

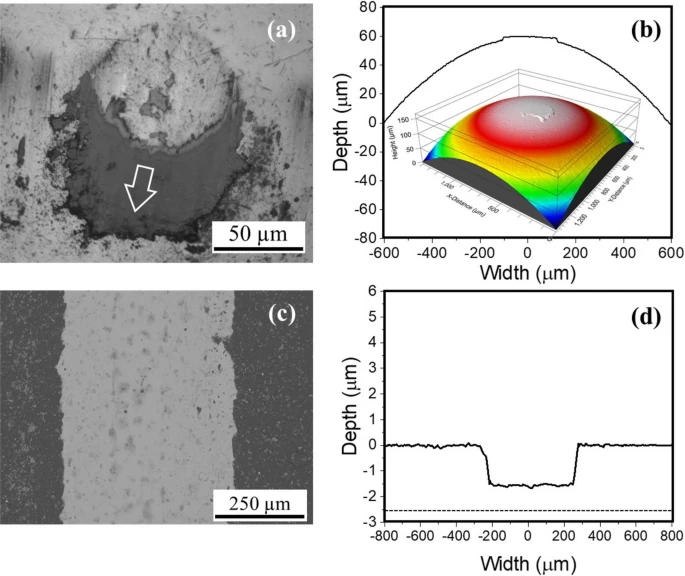

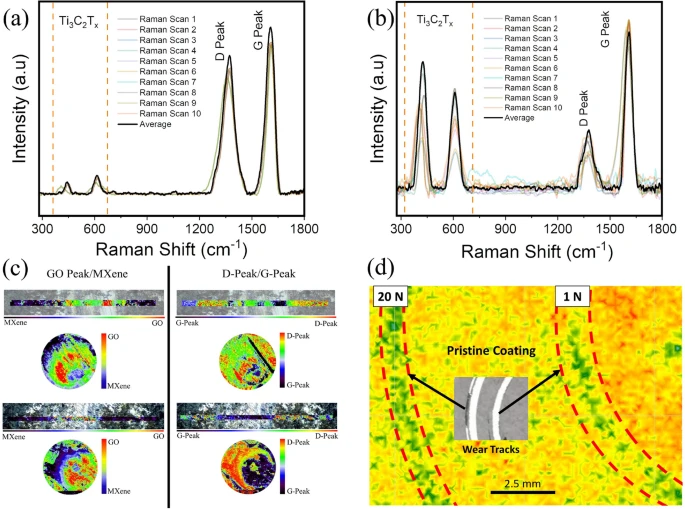

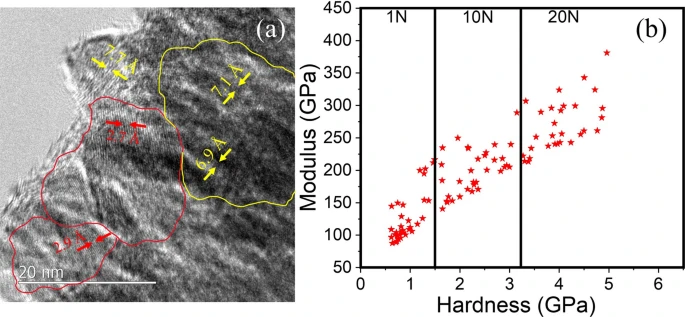

Development of solid lubricant materials that render reliable performance in ambient conditions, are amenable to industrial size and design complexities, and work on engineered surfaces is reported. These coatings are composed of Ti3C2Tx-Graphene Oxide blends, spray-coated onto bearing steel surfaces. The tribological assessment was carried out in ambient environmental conditions and high contact pressures in a ball-on-disc experimental set-up. The evaluation yielded that the use of Ti3C2Tx-Graphene-Oxide coatings led to substantial reduction in friction down to 0.065 (at 1 GPa contact pressure and 100 mm/s) in comparison to the uncoated of single-component-coated surfaces, surpassing the state-of-the-art. The coatings also provided excellent protection against wear loss of the substrate and counter-face. The results were explained based on the observations from Raman spectroscopy, scanning electron microscopy, transmission electron microscopy, and nanoindentation measurements. In operando formation of a dense, hard and stiff, dangling-bond-saturated tribolayer was observed to be the reason for the sustained lubricity even at high test loads and sliding speeds. This report presents the holistic exploration and correlation of structure-property-processing pertaining to the advancement of solid lubrication science.

Conclusions

This study reported the wear and friction behavior observed for a novel binary composite of Ti3C2Tx and Graphene Oxide synthesized using a spray-coating process. The coating was observed to provide excellent wear resistance on the substrate, and no detectable wear loss on the counterface ball. The friction values were significantly lower as compared to the state-of-the-art materials tested in ambient temperature and humidity conditions in contact pressures over 1 GPa. This behavior was explained based on observations from white-light-interferometry, scanning and transmission electron microscopy, Raman spectroscopy (point and areal mapping), and nanoindentation measurements, as the formation of a robust tribolayer that was composed of MXene and graphitic carbon transformed from Graphene Oxide compaction, which prevented metal-on-metal contact. This tribolayer was characterized to possess high hardness, stiffness, and surface passivation that enabled excellent lubrication behavior. The success of this simple coating synthesis advances the technology readiness of solid lubricants for complex and real-world applications.

- Previous: 3D MXene Architectures

- Next:

mxene academic

mxene academic

17365039012.php

17365039012.php