1. Article overview

In this paper, Sb ultrafine particles were cleverly modified onto flexible multilayer Ti3C2T (f-Ti3C2Tx) nanosheets through a simple electrostatic adsorption and annealing process, and Sb pillared Ti3C2Tx (Sb/p-Ti3C2Tx) composite materials were prepared. Benefiting from the enhanced dynamic properties of highly conductive pillared f-Ti3C2Tx and ultrafine Sb nanoparticles, the composite exhibits a reversible charging capacity of 438.1 mAh g-1 at 50 mA g-1 and 126.6 mAh g- at 2 hours 1 High retention rate. In addition, the strong interaction between Sb and Ti3C2Tx through the Ti-O-Sb chemical bond gives the composite high structural stability, leading to good cycle sustainability. And for the first time successfully integrated the dual advantages of MXenes low-layer state and pillar technology into MXene-based SIB composites, which can overcome the shortcomings of Sb anodes, and realize the development of columnar few-layer MXene composites in SIBs, and promote MXenes Commercialization process in SIBs.

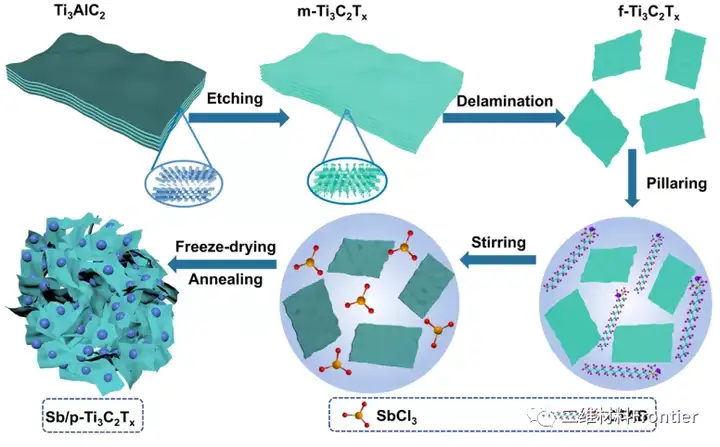

Figure 1. Schematic diagram of the preparation of f-Ti3C2Tx MXenes and Sb/p-Ti3C2Tx composites.

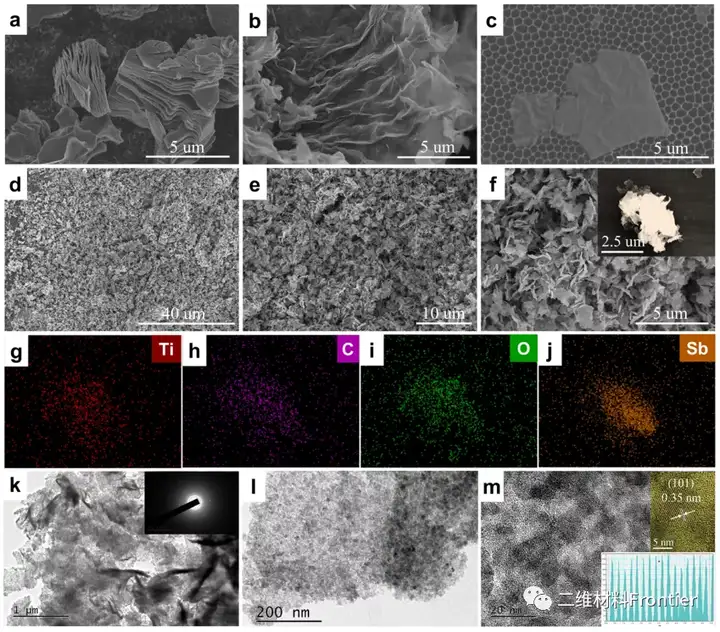

The synthesis process of f-Ti3C2Tx and Sb/p-Ti3C2Tx composites is shown in Figure 1. The accordion-like m-Ti3C2Tx is synthesized by etching the Al layer of Ti3AlC2 MAX phase. Subsequently, few-layered or single-layered Ti3C2Tx nanosheets were prepared by ultrasound in water. The production rate and production efficiency of f-mxens prepared by multi-layer mxens can be greatly improved by combining step-by-step stratification and liquid-phase flocculation technology. The interlayer spacing of Ti3C2Tx is expanded by cetyltrimethylammonium bromide (CTAB). Subsequent Sb3+ added in the form of SbCl3 is easily inserted into the Ti3C2Tx interlayer through an ion exchange process, or due to electrostatic attraction, adheres to the surface through the interaction between Sb3+ (positive) and f-Ti3C2Tx (negative), resulting in the formation of flocculation. After freeze-drying and annealing treatment, the residual CTAB volatilizes and the antimony precursor is reduced to metal antimony nanoparticles, thereby obtaining Sb/p-Ti3C2Tx.

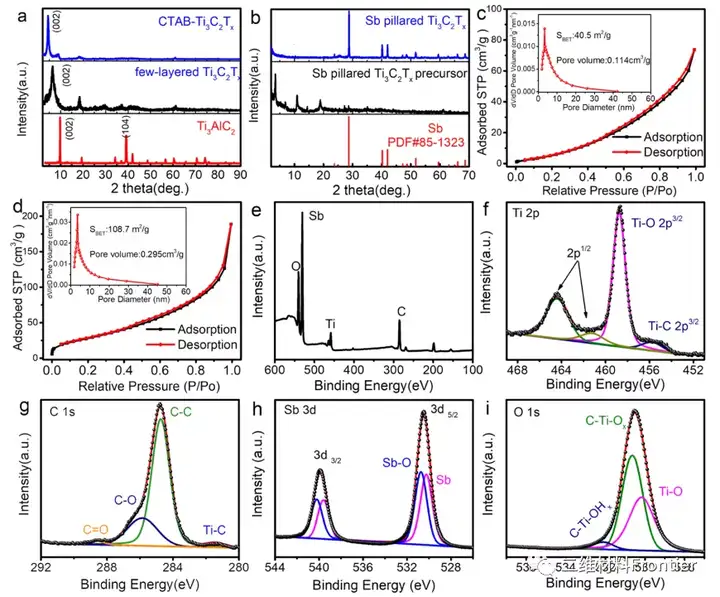

Figure 2. XRD, BET and XPS characterization of Sb/p-Ti3C2Tx composites.

The XRD pattern shows that the precursor of Sb is in an amorphous state. After the annealing process, the precursor of Sb was successfully transformed into metallic Sb (PDF#85-1323; Figure 2b). The BET results showed that the specific surface and pore volume increased significantly after being decorated with Sb nanoparticles. The increased specific surface area mainly comes from the ultrafine Sb particles, which can provide abundant active sites and facilitate the rapid acquisition of Na+.

Figure 3. (a) Scanning electron microscope image of accordion-like m-Ti3C2Tx. (b) Scanning electron microscope image of f-Ti3C2Tx powder. (c) Scanning electron microscope image of f-Ti3C2Tx on AAO film. (d−f) Scanning electron microscope image of Sb/p-Ti3C2Tx composite material. (g−j) Based on the corresponding element mapping of Ti, C, O, Sb in the illustration in (f). (k−m) TEM and HRTEM of Sb/p-Ti3C2Tx composite materials.

SEM results show that m-Ti3C2Tx is accordion-like. After the layering process, f-Ti3C2Tx MXenes can be obtained with a layered morphology with slight wrinkles on the surface. Figure 3d-f shows that after being synthesized with Sb nanoparticles, Ti3C2Tx has a layered structure, except that the thickness of Ti3C2Tx is significantly increased due to partial insertion of Sb. The EDS element mapping shows a uniform composite of Sb. Transmission electron microscopy shows that there are no Sb nanoparticles on the MXene matrix. The aggregation (Figure 3l). The selected area electron diffraction (SAED) pattern shows the polycrystalline state of Sb nanoparticles and Ti3C2Tx (inset of Figure 3k). High-resolution transmission electron microscopy (HRTEM) shows that monodisperse silver nanoparticles around 10nm are uniformly embedded in the conductive Ti3C2Tx matrix. Accurate measurement shows that the d-spacing is 0.35nm, which corresponds to the (101) plane of metal Sb.

Figure 4.29μm thick MXene film performance.

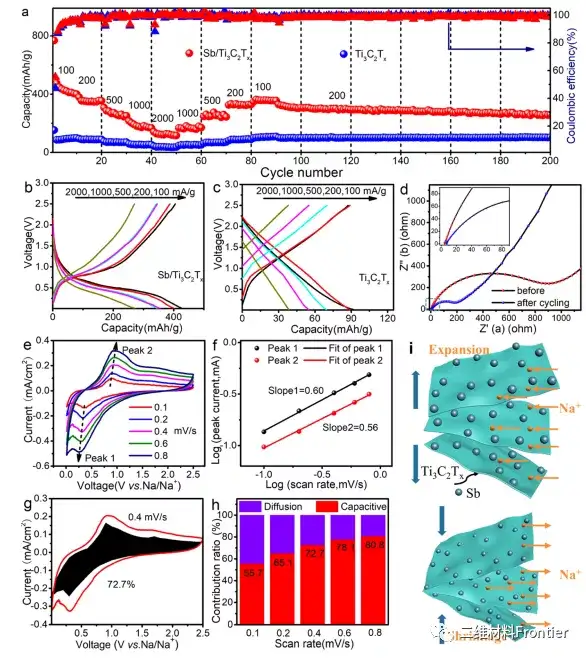

Figure 4a shows that when the rate is increased from 100 to 2000mA g−1, the capacity retention rate of bare f-Ti3C2Tx reaches 38%. Figure 4b-c shows that the material has good structural stability. Figure 4d shows that compared with the fresh electrode value before the cycle, the charge transfer impedance of the composite material is significantly reduced, reflecting the effective activation process of the electrochemical contact between the electrode and the electrolyte, and due to the cyclic ion insertion/deintercalation and partial insertion of Sb The interlayer spacing of flexible Ti3C2Tx increases due to volume expansion. As shown in Figure 4g, at a scan rate of 0.4 mV−1, the integrated result of the capacitive current response quantitatively separated from the total current response shows a higher ratio of 72.7%. The high capacitance contribution ratio is the reason for the excellent rate performance of the Sb/p-Ti3C2Tx composite, which is due to the excellent physical and chemical properties, advanced structure and ingenious cooperation. As shown in Figure 4i, the flexible f-Ti3C2Tx sheet with increased interlayer spacing has highly reversible expansion and contraction, which is conducive to cycle stability and rapid Na+ diffusion kinetics.

Third, the full text summary

This article reports a layered Sb/p-Ti3C2Tx composite material in which part of the active Sb is intercalated between the layers through a pillaring process combined with electrostatic adsorption and annealing, and ultrafine Sb nanoparticles are tightly fixed on the f-Ti3C2Tx. The flexible f-Ti3C2Tx matrix prepared by the modified solution phase flocculation method is an ideal carrier for Sb nanoparticles by constructing a highly efficient conductive network and generating strong interfacial interactions. It can prevent particles from crushing and agglomerating during the continuous insertion/extraction of Na+ , Thereby improving conductivity and structural stability. In addition, Sb nanoparticles are uniformly distributed on the surface and interface of Ti3C2Tx, acting as a space fence to inhibit the agglomeration and collapse of Ti3C2Tx nanosheets. The synergistic effect between Ti3C2Tx matrix and Sb ultrafine particles is the reason for achieving excellent electrochemical sodium storage performance with high retention rate and long cycle stability. Sb/p-Ti3C2Tx composite material shows the superiority of f-MXenes as the anode matrix of sodium-ion battery, its volume fluctuates sharply, and its conductivity is insufficient. This work further broadens the application range of f-MXenes, provides a feasible strategy for SIB to design high-performance pillared MXene-based composites, and expands the preparation and application of pillared MXene-based composites. Surveillance and security protection have great application prospects.

Article link:

https://pubs.acs.org/doi/10.1021/acsaem.1c01863.

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.