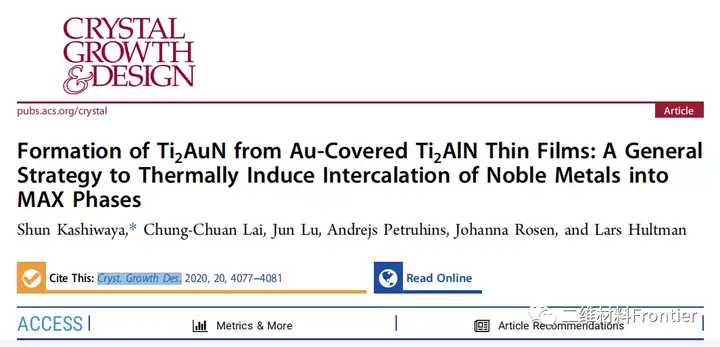

1. Article overview

By inserting precious metals into non-van der Waals ceramic compounds through thermal induction technology, a method of producing a new type of layered material is proposed. The author proved the exchange reaction of Au and the carbides of the MAX phase of the A layer with a large number of combinations of A and M elements. Here, the article reported the first time that gold was used to replace Al in Ti2AlN MAX phase nitrides at high temperature without destroying the original layered structure. These results support the generalization of the Au insertion of the A element in the MAX phase with different combinations of M, A and X elements. In addition, the article puts forward the key factors to realize the exchange reaction: A element should have a chemical potential to dissolve or react with noble metal; noble metal should be inert to the initial metal carbide/nitride; it is necessary to choose to allow noble metal and A element to diffuse each other in equilibrium The reaction temperature.

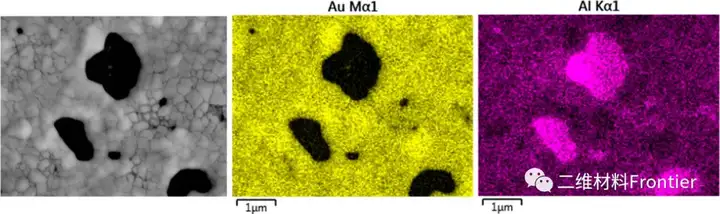

Figure 1. SEM image of Ti2AlN deposited by gold after annealing (left) and surface mapping: Au (middle) and Al (right).

Figure 1 shows the SEM/EDX of the surface of the Ti2AlN film deposited by Au after annealing. Aluminum is separated from the A layer of Ti2N and diffused and deposited into the gold layer to form Al agglomerates on the surface.

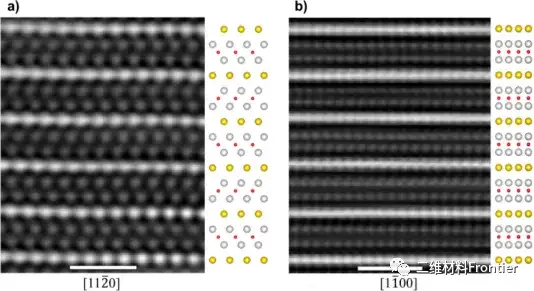

Figure 2. HRSTEM images of Ti2AlN covered with annealed gold taken along the axis of [1120](a) and [1100](b). The yellow, gray and red balls represent Au, Ti and N atoms, respectively, showing the morphology of Ti2AuN. Scale bar, 1nm.

The brightness in STEM is proportional to the atomic mass transmitted by the electron beam. The atomic arrangement corresponds to the M2AX phase: a typical laminar flow structure consists of heavy elements, Au, and alternating Ti2N layers. Each Ti2N sheet is stacked on top of each other, sandwiched into a zigzag shape by a single layer of gold. This obviously means that the external diffusion of aluminum caused by high temperature is due to the internal diffusion of gold without destroying the original layered structure.

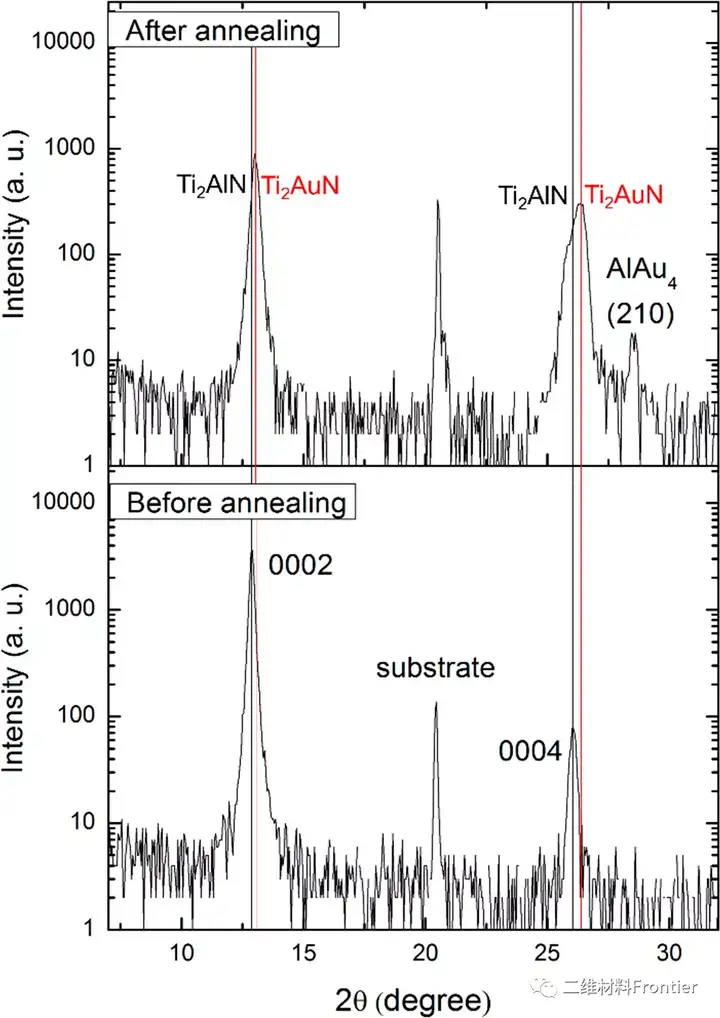

Figure 3. XRD patterns of Ti2AlN covered with gold before and after annealing.

Figure 3. shows the diffraction peaks at about 13° and 26° corresponding to (0002) and (0004) of Ti2AlN, respectively. The peak at about 28° after annealing is due to the Al-Au intermetallic phase formed on the top of the sample due to the diffusion of Al into Au. This is because when the high temperature rises, Au and Al diffuse each other between Al2Au, AlAu, AlAu2, Al2Au5 and AlAu4, forming different intermetallic phases.

3. Full text summary

In summary, the article proves that the thermally induced Au insertion into Ti2AlN can form Ti2AuN phase. It also discusses the exchange reaction mechanism of noble metals and A layer, and puts forward some suggestions on the key factors of the corresponding reaction. Al should be negatively heated with Au at the annealing temperature; the layered structure of the original Mn+1AXn is stable to the exchange element, and the appropriate annealing temperature must be selected to meet all the above requirements. The results of the article support the versatility of the insertion process of Mn+1AXn, which contains a large number of combinations of M, A, and X elements. They also pave the way for the exploration of new layered transition metal carbides/nitrides with customized chemical and physical properties. In addition, this strategy should not only insert noble metals into the Mn+1AXn phase film, but also insert the corresponding volume or granular Mn+1AXn phase.

Article link:

https://dx.doi.org/10.1021/acs.cgd.0c00355

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.