已传文件:photo/1631586161.png

1. Article overview

Although solar energy is promising in water purification, there is still room for further improving the efficiency of solar steam generation. In this article, the author created an environmentally energy-enhancing solar steam by immersing a cellulose acetate fiber-based cigarette filter (CF) in a polyvinyl alcohol (PVA) aqueous solution, then freeze-drying and decorating with MXene flakes. Evaporator. The existence of MXene is to absorb solar light and convert solar energy into heat energy to achieve efficient water evaporation, while the porous PVA network generated in the filter pores during the freeze-drying process accommodates dispersed MXene sheets and connects CF and MXene. Due to the construction of the PVA/MXene network in the CF porous structure and the hydrophilicity of MXene and PVA, the synthesized MXene/PVA modified CF (MPCF) has a high degree of hydrophilicity and can quickly transfer water upwards.

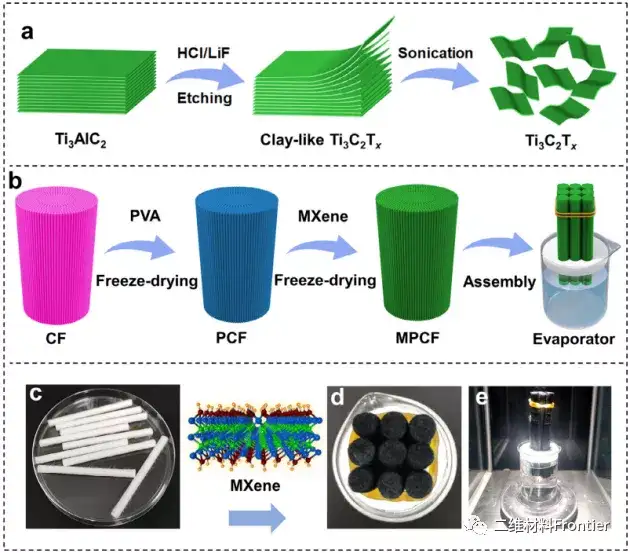

Two, graphic guide

In the above figure, a) a schematic diagram of the preparation of the MXene sheet; b) a schematic diagram illustrating the manufacturing of the MPCF evaporator; c) PCFs; d) MPCFs and e) digital images of the assembled MPCF solar steam generating device.

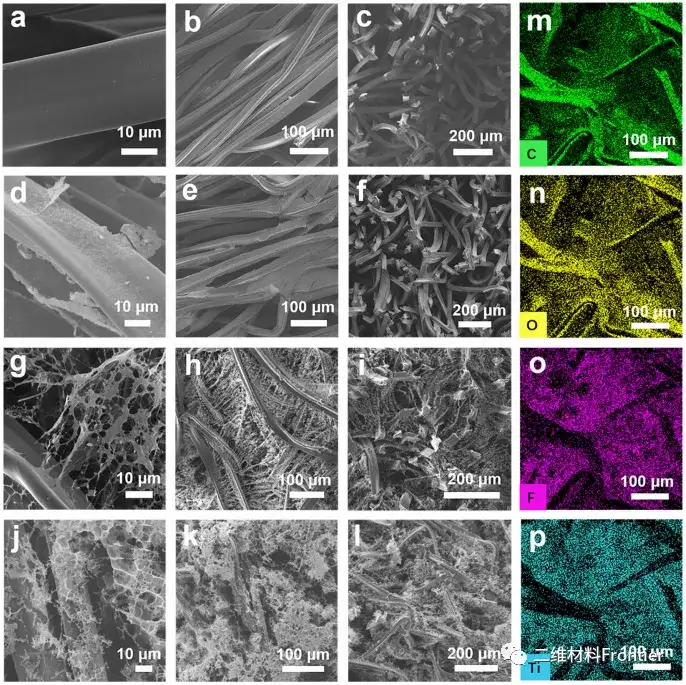

Figure 2. Scanning view of the structure of the material.

Among them, a-c) CF, d-f) MCF, g-i) PCF and j-l) MPCF scanning electron microscope images. M, C, n, O, F, p, Ti element mapping image of MPCF.

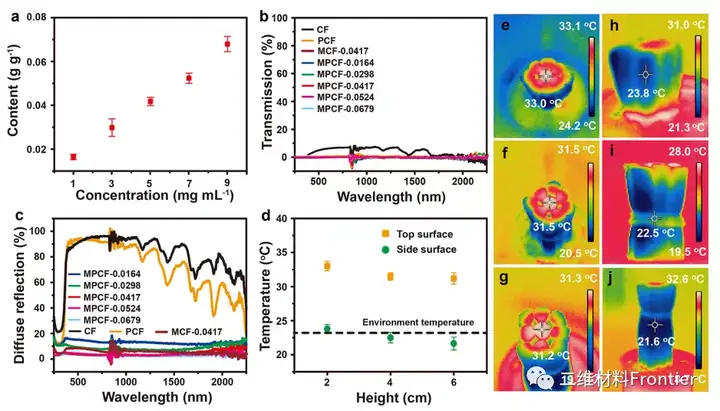

Figure 3. Solar-thermal energy conversion performance of CF, PCF, MCF, MPCF evaporators.

In the figure above, a) the relationship between the MXene content used in MPCF and the initial concentration of the MXene dispersion, b) the transmission spectrum and c) the diffuse reflectance spectra of CF, MCF, PCF and MPCFs with different MXene content. d) The surface temperature of the top and sidewalls of MPCFs at different exposure heights during solar solar vapor generation. Photographs of the top surface temperature of the MPCF with exposure heights of h)2, i), 4, j)6cm.

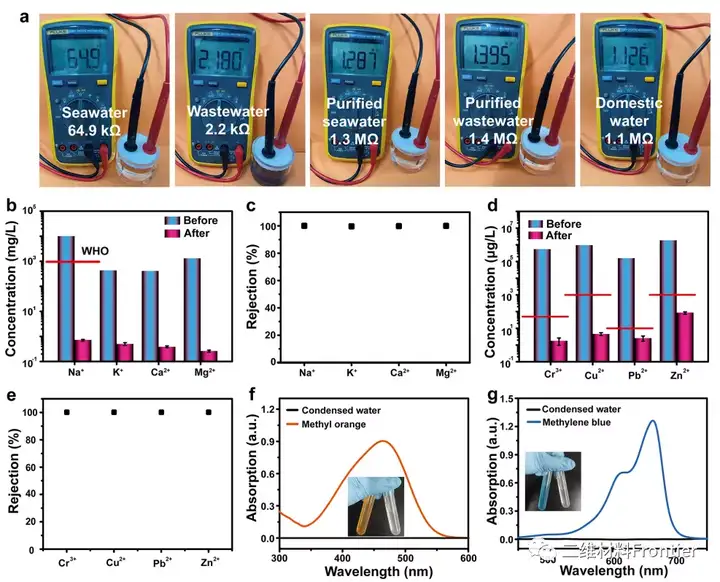

Figure 4. MPCF s desalination and wastewater purification capabilities.

In the figure above, a) Resistance to sea water and wastewater before and after solar thermal evaporation. b) The salt ion concentration of sea water before and after solar thermal evaporation treatment. The red line represents the WHO drinking water standard. c) The rejection rate of salt ions. d) The concentration of heavy metal ions in wastewater before and after solar thermal evaporation treatment. The red line refers to the WHO drinking water standard. e) Ion rejection rate of heavy metal ions. The decontamination ability of MPCF on f) methyl orange is simulated (the illustration shows the color change of methyl orange before and after purification). g) Methylene blue (the illustration shows the color change of methylene blue before and after purification).

3. Full text summary

In summary, by creating a PVA/MXene network in the porous CF structure, a solar evaporator with enhanced environmental energy was prepared. The hydrophilicity of MXene, PVA and CF makes the MPCF solar-driven water evaporator has high hydrophilicity and fast upward transportation of water. MXene flakes provide excellent solar-thermal energy conversion efficiency, while the porous PVA network can accommodate MXene flakes and connect CF and MXene to each other through hydrogen bond interaction, thereby preventing the separation of MXene flakes and CF fibers and improving the efficiency of the MPCF evaporator. Cycle stability. In addition, using the three-dimensional characteristics of the evaporator, a temperature defect between the side wall and the environment is established during the solar thermal evaporation process, ensuring that additional energy is obtained from the surrounding environment through thermal convection and radiation. Therefore, the MPCF evaporator has an ultra-high solar steam generation rate of 3.38kgm-2h-1, and a solar-thermal energy conversion efficiency of 132.9%, which is better than the reported results. With its excellent steam generation performance, MPCF has shown great potential in solar-driven seawater desalination and wastewater purification.

Article link:

https://doi.org/10.1016/j.jcis.2021.08.043

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.