hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

With the extensive use of electronic communication technology in integrated circuit systems and wearable devices, electromagnetic interference (EMI) has increased dramatically. The shortcomings of conventional rigid EMI shielding materials include high brittleness, poor comfort, and unsuitability for conforming and deformable applications. Hitherto, flexible (particularly elastic) nanocomposites have attracted enormous interest due to their excellent deformability. However, the current flexible shielding nanocomposites present low mechanical stability and resilience, relatively poor EMI shielding performance, and limited multifunctionality. Herein, the advances in low-dimensional EMI shielding nanomaterials-based elastomers are outlined and a selection of the most remarkable examples is discussed. And the corresponding modification strategies and deformability performance are summarized. Finally, expectations for this quickly increasing sector are discussed, as well as future challenges.

Convincing candidates of flexible (stretchable/compressible) electromagnetic interference shielding nanocomposites are discussed in detail from the views of fabrication, mechanical elasticity and shielding performance.

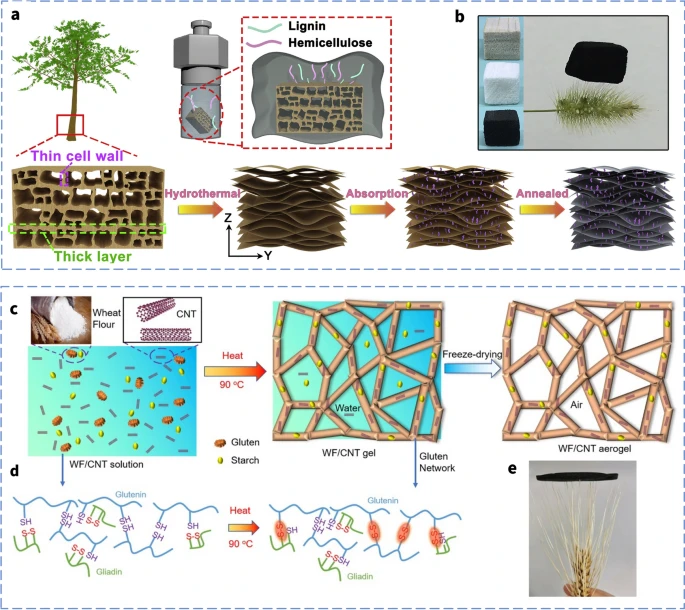

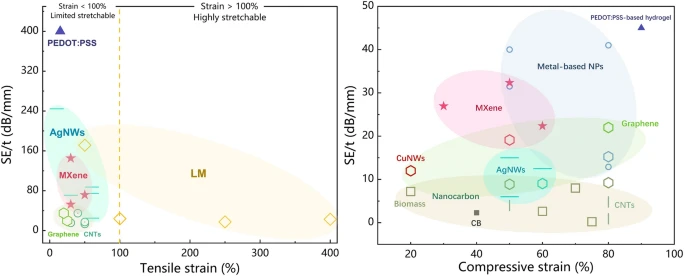

Detailed summary of the relationship between deformation of materials and electromagnetic shielding performance.

The future directions and challenges in developing flexible (particularly elastic) shielding nanocomposites are highlighted.

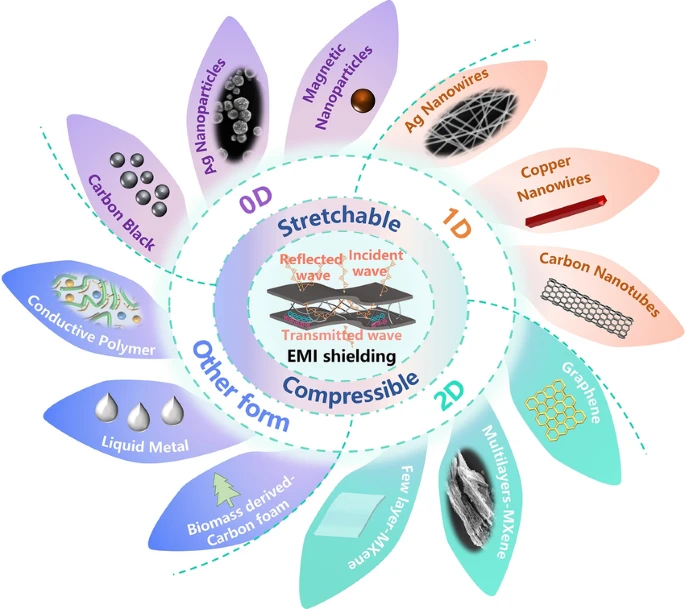

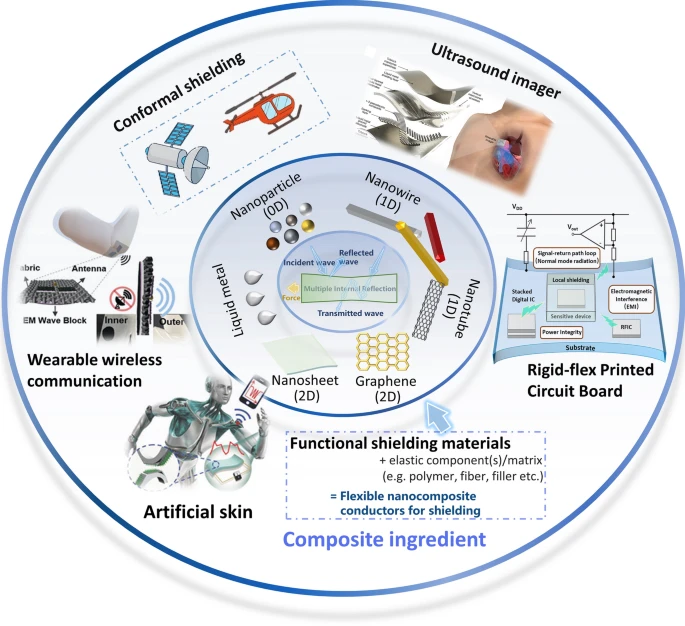

图1. Schematic of the materials and applications of flexible nanocomposite conductors for EMI shielding.

图2. EMW propagation model in EMI shielding material under stretching

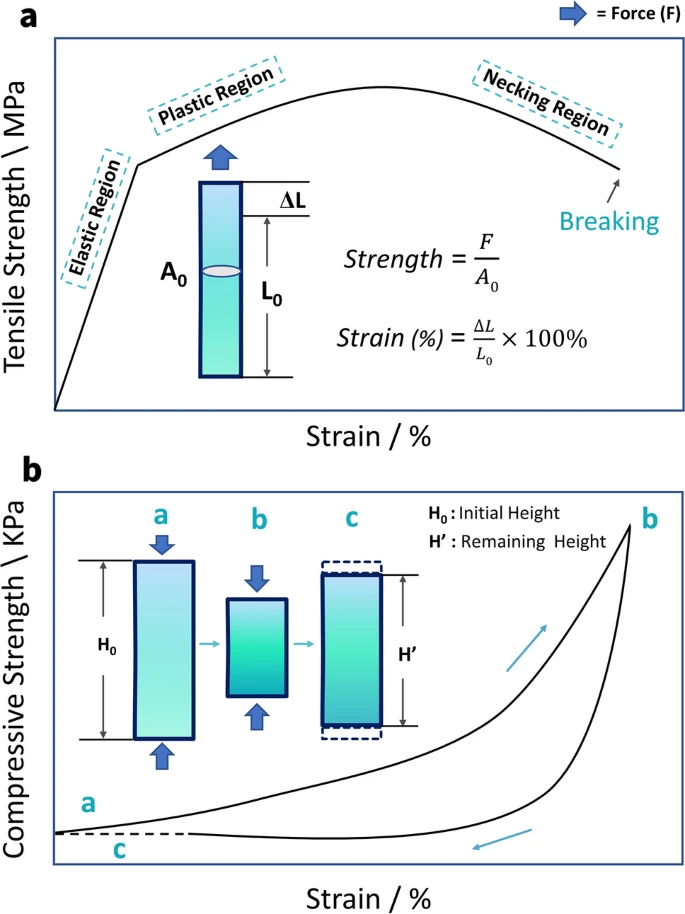

图3. a Tensile strength–strain of stretchable materials. Inserts are representation of tensile load to a wire and corresponding equations. b Compressive strength–strain curves of compressible materials. Inserts are the schematic diagram showing the compression-recovery process

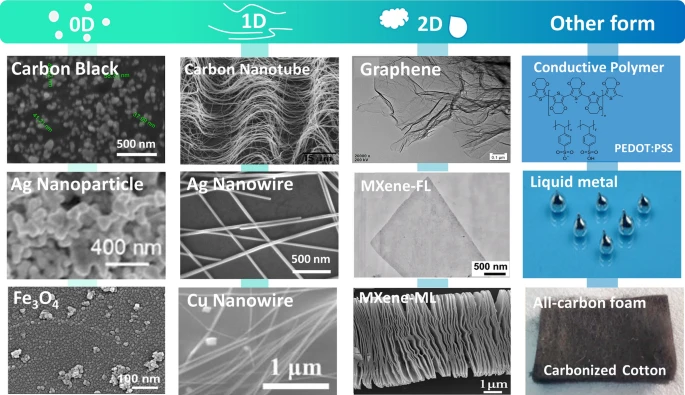

图4. Commonly used electronic fillers for elastic EMI shielding materials.

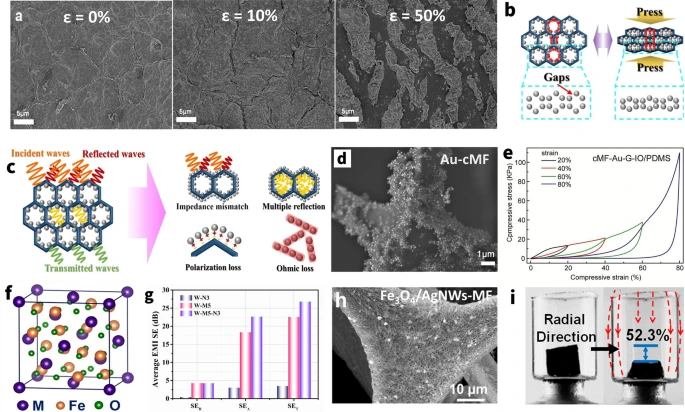

图5. Nanoparticle based elastic EMI shielding composites.

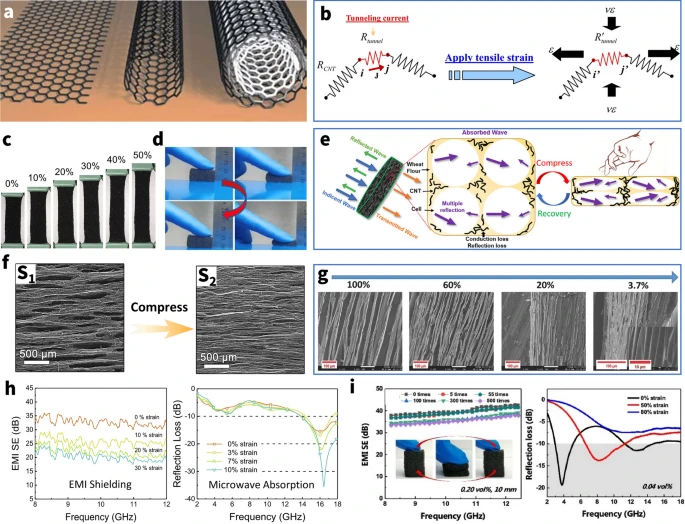

图6. Basic forms of planar graphene sheet, SWCNT, and MWCNT

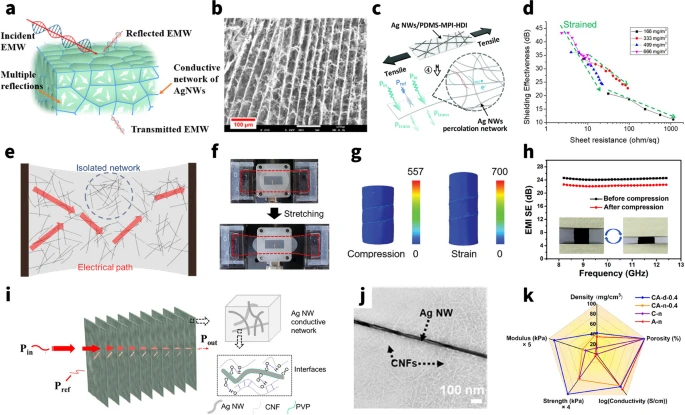

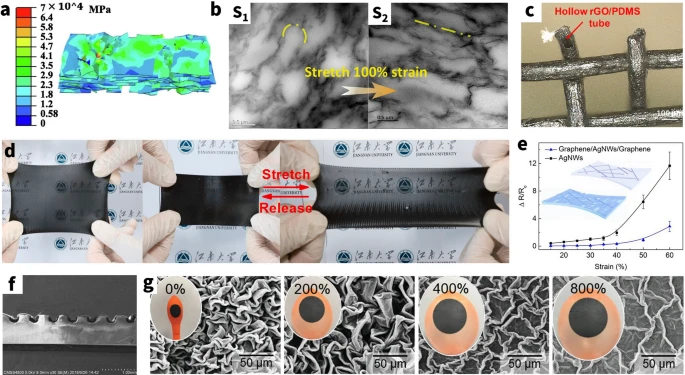

图7. AgNWs-based EMI shielding composites.

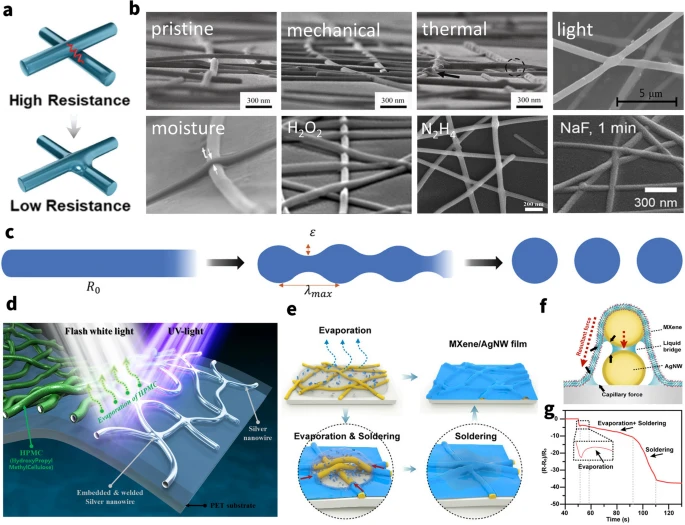

图8. Welding techniques for AgNWs percolation network.

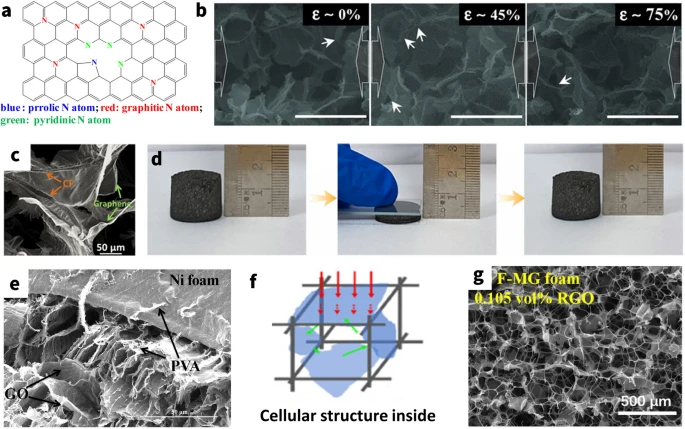

图9. Schematic map of N-doped graphene.

图10. Graphene-based stretchable EMI shielding composites.

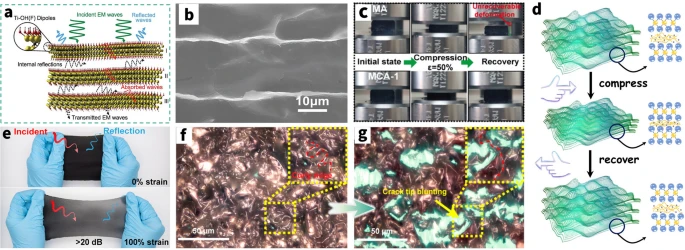

图11. Proposed EMI shielding mechanism of MXene flakes.

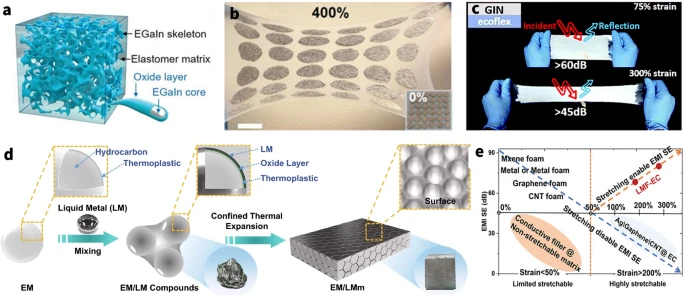

图12. Liquid metal-based elastic EMI shielding composites.

图13. Biomass-derived carbon composites-based elastic EMI shielding composites.

图14. Comparison of EMI SE after numerous strain cycles and tensile/compressive strain of the elastic EMI shielding materials.

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |