hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

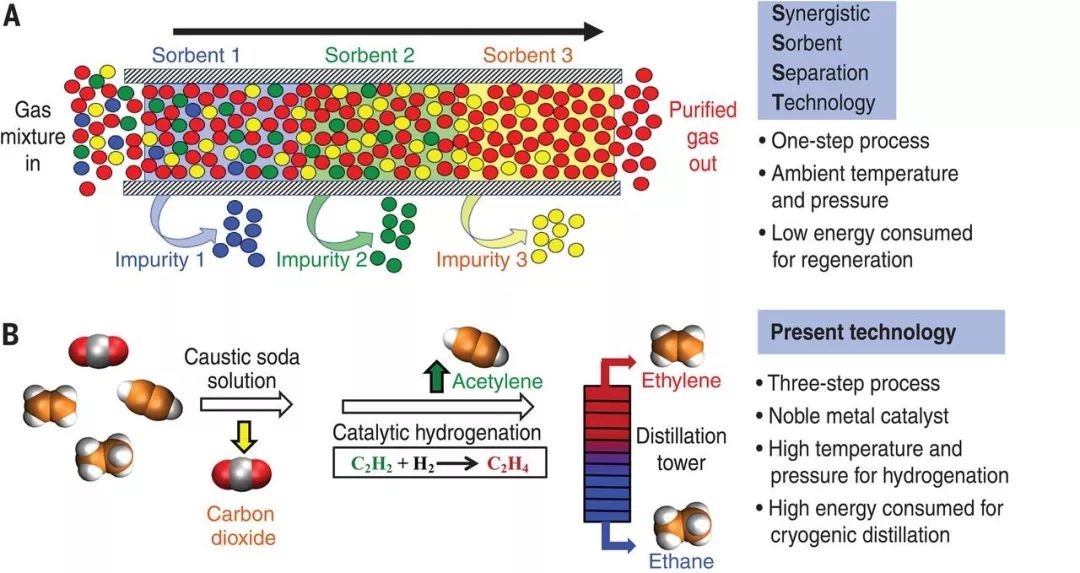

The purification of ethylene (C2H4) is a key process in the chemical industry. At present, energy-intensive processes such as chemical adsorption (CO2 removal), catalytic hydrogenation (C2H2 conversion) and cryogenic distillation (C2H6 separation) are mainly used. Although physical adsorbents or membrane separation techniques may reduce energy input, many problems remain unresolved by removing multiple impurities (especially trace impurities) step by step. Kai-Jie Chen of Northwestern Polytechnical University and David G. Madden of Limerick University synthesized a super-selective microporous MOFs material that is easy to regenerate, and developed a synergistic adsorbent separation method based on MOFs materials. The ternary (C2H2/C2H6/C2H4) or quaternary (CO2/C2H2/C2H6/C2H4) gas mixture is separated step by step in a packed bed, ultimately obtaining high purity ethylene in a low energy manner.

Kai-Jie Chen et al.Synergistic sorbent separation for one-step ethylene purificationfrom a four-component mixture,Science 2019.

https://science.sciencemag.org/content/366/6462/241

source:http://www.nanoer.net

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |