hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

Two-dimensional transition metal carbides or carbonitrides have received widespread attention since their successful preparation in 2011. Because their surfaces contain functional groups, they are hydrophilic and can be used for heavy metal ion adsorption and desalination treatment. As the active substrate of the catalyst; it has a large specific surface area, good electrical conductivity, and can also be used in electrochemical energy storage equipment. In the preparation of MXene materials, the A element in the MAX phase is etched away with an etchant, which will form a wide interlayer distance. When external pressure is applied, it can cause the interlayer distance to change. Therefore, some researchers have developed based on Ti3C2–MXene A highly flexible, high-sensitivity piezoresistive sensor.

Compared with the commonly used methods of preparing interdigital electrodes, such as photolithography, the methods proposed by researchers are more simple, easy to use, non-toxic and harmless, and low in cost. In short, the Ti3C2–MXene-based sensor consists of three layers. The MXene layer is located between the interdigitated electrode and the fabric layer. First, an interdigital structure is printed on the polyimide film by ink, and then the interdigital is formed by magnetron sputtering metal. The electrode further forms a soft substrate and a conductive path; then the polyimide film is immersed in an absolute ethanol solution of MXene, and the fabric with a hierarchical structure is taken out and dried as a protective layer. To improve stability, PDMS is used to seal the entire equipment.

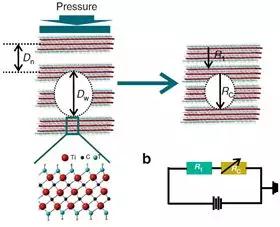

Figure 1 shows the working principle of the Ti3C2–MXene-based piezoresistive sensor. The distance between two adjacent layers will be reduced by the external force, resulting in a decrease in internal resistance and thus an increase in conductivity; Figure 1.b is equivalent Circuit diagram, the total resistance of the entire circuit will decrease when an external force is applied.

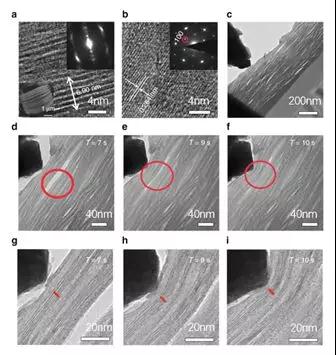

Figure 2: MXene structure and in-situ TEM images of structural changes under external force a, b) are cross-sections and plan views of Ti3C2–MXene, respectively; c) is an in-situ force device; df) is a wider interlayer distance Interlayer variation of MXene under external force, 12nm (7s), 3nm (9s) and 0nm (10s); gi) is the interlayer variation of MXene with narrower interlayer force under external force, 5.23nm (7s), 4.98nm (9s) and 4.81nm (10s);

Figure 2 shows the in-situ transmission electron microscope used to study the microdynamics of the MXene piezoresistive sensor. The MXene layer spacing will be reduced by external forces. When the external force is withdrawn, reversible recovery can also occur. Easily compressed.

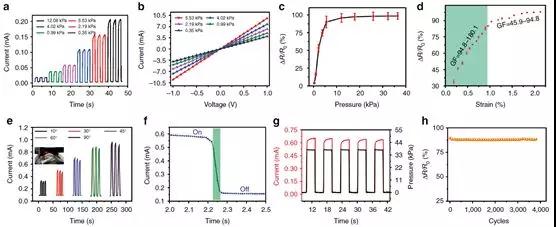

Figure 3: MXene-based sensor response to pressure

Exploring the piezoresistive effect of MXene-based sensors under different applied pressures, the IT curve shows that when the pressure is less than 13kPa, the current monotonically increases with the pressure, and shows a stable and continuous characteristic in each loading and unloading (Figure 3. a), a good linear relationship indicates that an ohmic contact is formed between the MXene and the interdigital electrode (Figure 3.b); when the pressure is less than 5kPa, the ΔR / Roff value increases sharply with the increase in pressure due to the change in the MXene material layer spacing When the pressure is greater than 5kPa, the pressure causes the tightness between MXene blocks to increase. At this time, the ΔR / Roff value changes slightly (Figure 3.c); within a very small strain range of 0.19–0.82%, the MXene-based sensor It has extremely high sensitivity, and the change is not significant within the range of 0.82% -1.80% (Figure 3.d); because it can still maintain a good response at different bending angles (Figure 3.e), it can be applied to explore human motion , And the fastest response time is less than 30ms (Figure 3.f); MXene-based sensors have mechanical durability, after the cyclic loading-unloading 4000 times, the sensor signal only shows a small attenuation.

Based on the excellent sensing characteristics and wearability of this sensor, it can be applied to the corners of the eyes, cheeks, throat, fingers, knees, etc. to explore human activities, and it can even respond to knee joint movements quickly through the microcircuit Bluetooth system. The portable and wearable MXene-Ti3C2TX piezoresistive sensor has broad application prospects in the field of wearable devices and electronic skin, further expanding the application field of MXene materials.

References: Yanan Ma1, Nishuang Liu1, Luying Li1, Xiaokang Hu, Zhengguang Zou, Jianbo Wang, Shijun Luo & Yihua Gao *. A highly flexible and sensitivepiezoresistive sensor based on MXene with greatly changed interlayer distances. Nature Commucation. 8: 1207.

DOI: 10.1038 / s41467-017-01136-9

Source-WeChat public account: OIL Lab

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |