hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

Research Background

Due to the unique physical and chemical properties, MXene been widely studied , involving a plurality of field, MXene preparation are MXene base application, a large amount is related to the preparation MXene practical application , typically MXene release top-down approach, which peeling principle Decided the feasibility of large-scale preparation . Fewer layers MXene colloid , multi-layered MXene powder, a small layer of MXene powder MXene presence of the basic state, and perhaps imperfect place, but the efforts of researchers, which have achieved rapid mass production of , and all Applied for related patent protection. This time, we will introduce the mass preparation of MXene , especially the rapid mass preparation of few layers of powder .

Literature 1 : Large-scale preparation of few layers of M X ene colloid

Large-scale delamination of multi-layers transition metal carbides and carbonitrides “ MXene ”

Dalton Trans., 2015, 44, 9353–9358 .

brief introduction

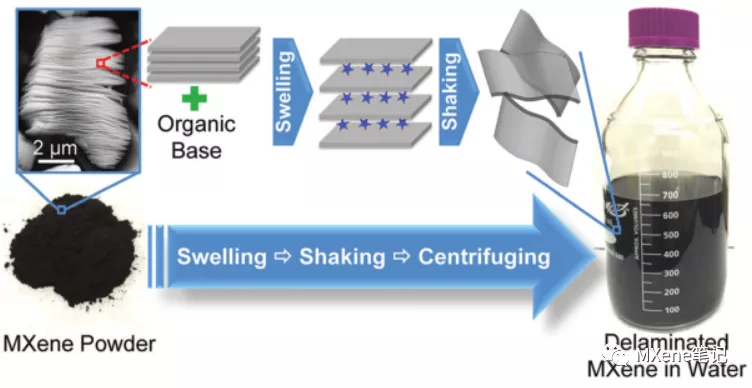

This paper reported that the organic base layer is interposed , through subsequent manual shaking, ultrasonic peeling way, a layer of less MXene large scale preparation of nanosheet, since the organic macromolecular material is used lye, i.e. T MAOH, of TBAOH the like, these large After the molecules are embedded in the multiple MXene layers, the interlayer distance is increased, and the interlayer force is weakened . After manual shaking or ultrasonic peeling of the instrument, a uniformly dispersed MXene nanosheet solution can be obtained . Filter, you can get a flexible self-supporting MXene film. Other organic bases , such as n-butylamine can be peeled V 2 CT X and of Ti . 3 the CNT X like MXene material. Unlike dimethyl sulfoxide intercalated release Ti . 3 C 2 T X , only Ti3 C 2 T x is valid . The preparation method of organic alkali intercalation - peeling can be applied to different MXene material systems. Due to the simple preparation method, coupled with the versatility of this method in peeling various MXenes , large-scale M X ene aqueous solution preparation.

Literature 2 : Large-scale preparation of multilayer M X ene powder

Scalable Synthesis of Ti 3 C 2 T x M X ene

Adv. Eng. Mater. 2020, 1901241 .

brief introduction

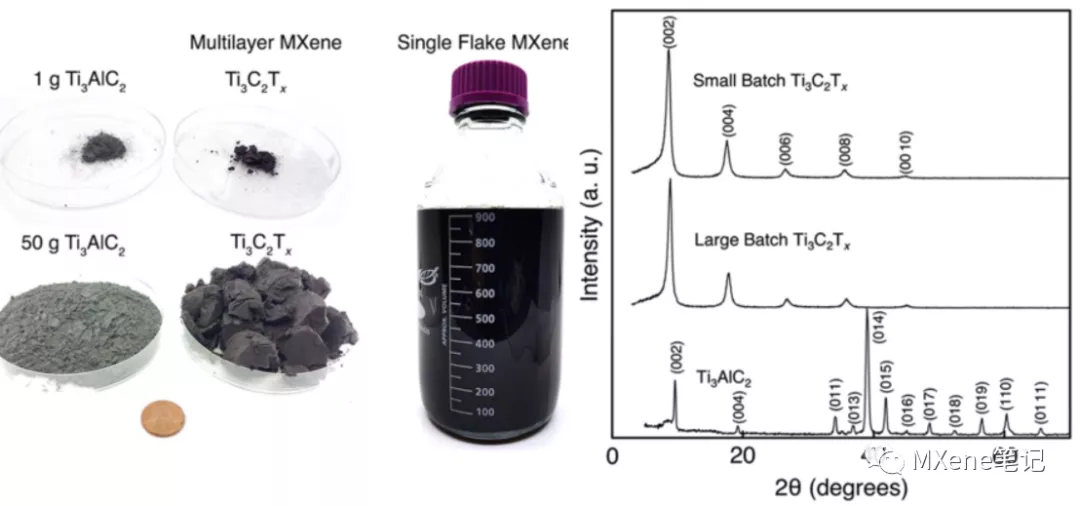

It is found in this paper that no matter whether a small amount of Ti 3 A l C 2 (1 g) is used for etching preparation , or a large amount of Ti 3 A l C 2 ( 50 g) is used for etching to prepare multiple layers of Ti 3 C 2 M X ene powder , preparation The characterization results of the obtained multilayer M X ene samples are basically the same, including the results of macro tests such as X RD , and the micro test characteristics such as S EM , which fully shows that Ti 3 A l C 2 M AX In addition to the use of larger reaction vessels and more etching solution , there is no detail requirement in other aspects. These results indicate that, according to similar principles, it is feasible to prepare MXene in large quantities for industrial application . Although the preparation of Ti 3 C 2 is taken as an example in this article , due to the similarity of M X ene , it is also effective for other MXene systems .

Literature 3 : Fast and large-scale preparation of a few layers of M X ene powder

Fast and Universal Solution-Phase Flocculation Strategy for Scalable Synthesis of Various Few-Layered MXene Powders

J. Phys. Chem. Lett. 2020, 11, 1247−1254 .

brief introduction

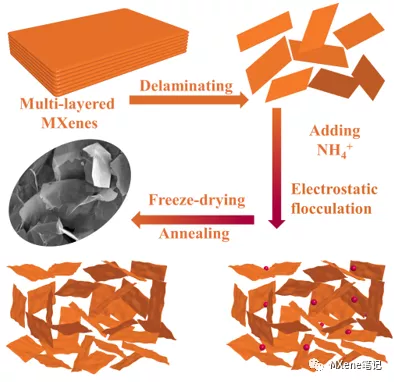

Although been achieved less layer MXene colloid , multilayer MXene powder large amount of preparation, and in the actual application process, in order to achieve better performance, more desirable is a material in a small layer state ( two -dimensional material layers less than 5 , specifically see reference . 1 - 2 ) , in addition, MXene nanosheet is easily oxidized in an aqueous solution degradation , prepared in M X- ENE material is preferably as small layer powder state , to facilitate the storage of anhydrous oxygen-free environment . By freeze-drying, the MXene solution can be lyophilized to a powder state, but the whole process is time-consuming and yieldsVery few , and there is agglomeration .

Han Weiqiang Zhejiang University research group from MXene starting basic properties ( surface electronegativity ) , systemic proposed liquid flocculated policy ( including ammonium ions method and an improved ammonium ion method , see ref . 3 - . 4 ) . Adding positively charged ammonium ions to it destroys the electrostatic equilibrium state of the M X ene solution . With the automatic electrostatic precipitation of MXene nanosheets , the upper layer of water is drained, which can greatly save the time of cooling and drying . The flocculent precipitate was lyophilized, and finally the rapid preparation of a few layers of M X ene powder was achieved ( no agglomeration under low-power scanning electron microscope ) .

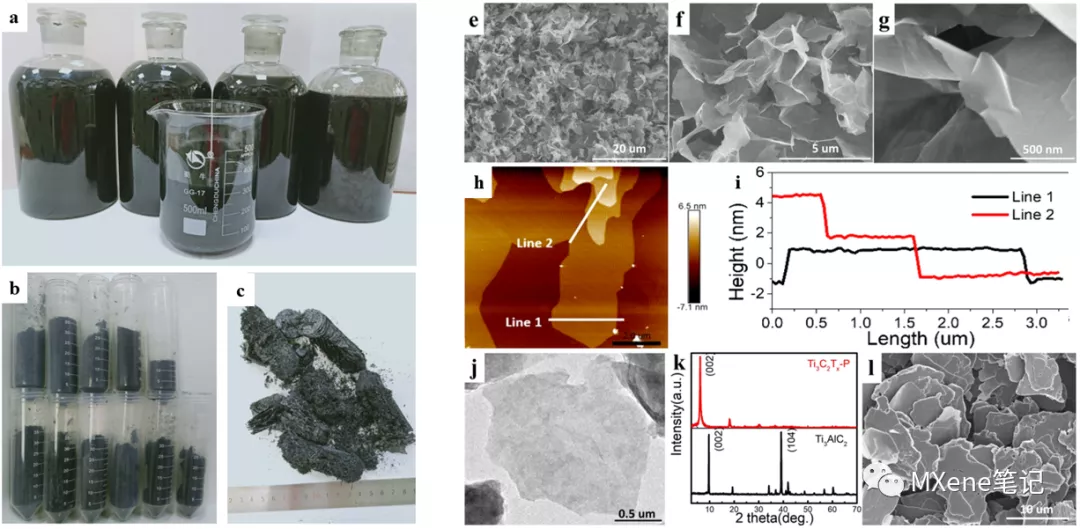

Liquid-phase flocculation - electrostatic sedimentation related physical map

Considering the original MAX phase particles of different sizes, different thickness, are etched multilayer M X- ENE exist where the size of substantially different sizes , M X- ENE ultrasound should not be peeled off across the board ( a uniform ultrasonic release time ) . This paper further proposed a method to gradually peeled , i.e. the peeling layer is less good M X- ENE nano- sheet promptly centrifuged collected, peeled not peeled ultrasound continued good ( after ultrasonic peeling, collected by centrifugation supernatant layer is less precipitate a multilayer , Add water to the precipitate and continue ultrasonic peeling, so repeated) , improve the yield of few layers of M X ene nanosheets , and avoid the generation of M X ene fragments . OF also be repeatedly peeled off, the precipitate after centrifugation were characterized and found that S the EM was rubble films like (Thick ) , X- the RD the current M X- ENE characteristic peaks were peeled off after precipitation repeated, not belonging to the multilayer peelable M X- ENE . In the subsequent electrostatic coagulation link, the centrifugal assisted method reduces the coagulation time and improves the preparation efficiency. As a result, an improved ammonium ion method ( including gradual peeling and centrifugal assisted sedimentation ) was formed , and finally a rapid mass production of a few layers of M X ene nanosheet powder was achieved . The whole preparation process is simple, all steps are scalable, or even all steps ( etching , peeling electrostatic coagulation , etc.) to put a large-scale without loss of M X- ENE nanosheet characteristics , great ofPractical application prospects .

Physical map and material characterization

Basic principle: the small layer of MXene nanosheets after stripping can exist stably in aqueous solution for a period of time ( the supernatant collected by centrifugation will not be oxidized in a short time ) , and the reason for the stable existence is that the surface of the nanosheets is negative electrostatic interaction between the nano-sheets are mutually exclusive, so that the M X- ENE does not occur agglomeration stacked in an aqueous solution, which is a considerable part of M X- ENE root cause start target application directly from an aqueous solution , if the addition of a positively charged with If the mass ( large volume and heavy mass ) is destroyed, the electrostatic equilibrium state is destroyed, and the automatic aggregation of M X ene nanosheets will occur . Among the positively charged groups, in view of the volatile ammonium salts, a subsequent segment can be removed by annealing, so choose the ammonium ion ( ammonia water, ammonium salts, such as the chemical nature of the unstable ammonium bicarbonate, easy to heat decomposition , heat At about 60 ℃, it decomposes into NH 3 21.5% and CO 2 55.7%, H 2 O 22.8% ) , in contrast, metal ions are difficult to remove in the powder state ( generally by washing to remove metal ions, and washing makes M X ene return to the solution state ) .

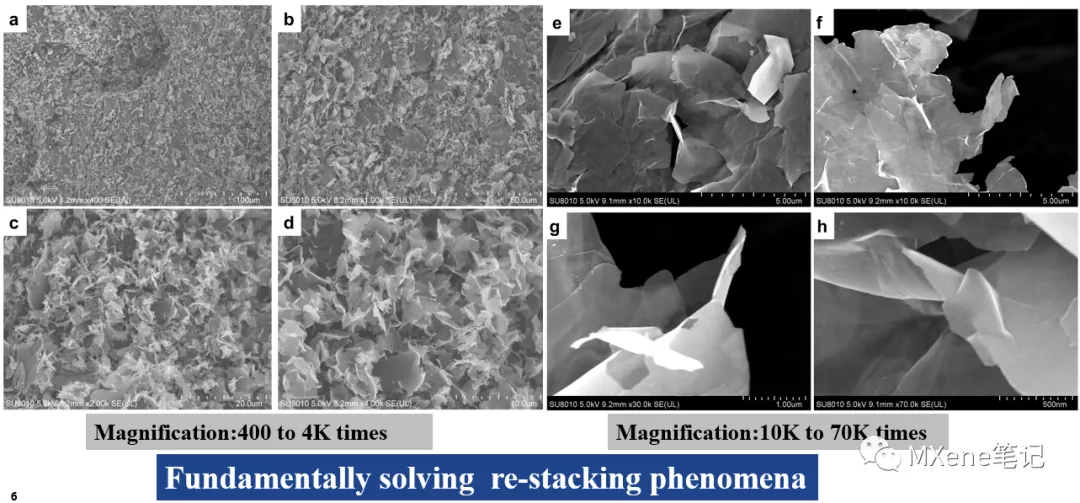

Material Characterization S the EM ( from . 4 00 times to . 7 0K)

The ammonium ion method and the improved ammonium ion method solve the problem of agglomeration of M X ene , and realize the rapid and large-scale preparation of a few layers of M X ene nanosheet powder , thereby avoiding the problem of easy oxidation of M X ene . Layer M X ene powder is stored in a water-free and oxygen-free environment, such as a glove box or sealed for storage , which is convenient for subsequent applications .

References :

[1] Ultrathin Two-Dimensional Nanomaterials. ACS Nano . 2015, 9, 9451−9469 .

[ 2] Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev.

2017, 117 (9), 6225−6331.

[ 3] Partial Atomic Tin Nanocomplex Pillared Few‑Layered Ti3C2Tx MXenes for Superior Lithium‑Ion Storage . Nano‑Micro Lett. (2020) 12:78 .

[ 4] Fast and Universal Solution-Phase Flocculation Strategy for Scalable Synthesis of Various Few-Layered MXene Powders . J. Phys. Chem. Lett. 2020, 11, 1247−1254

Related issues :

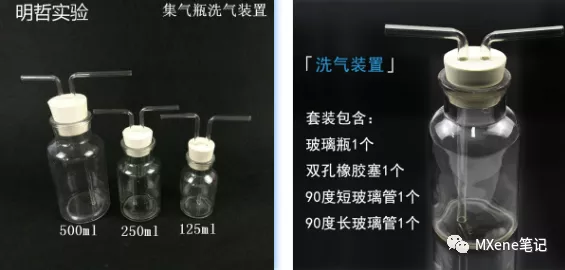

① How does MXene pass argon during ultrasound

Scouring the Po buy washing bottle, once it requires a plurality of through, latex catheter tube to the glass bottle together in series , can refer to FIG .

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |