hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

【Research Background】

Polymer materials have many outstanding characteristics such as high strength-to-weight ratio, excellent ductility, and ease of processing. Therefore, they have been widely used in aerospace, electrical appliances, transportation, energy and other fields. Flame retardant polymer materials with high ductility, high strength and high toughness are ideal materials for industrial applications. However, current material designs often fail to achieve a combination of high strength and high toughness without affecting polymer ductility. In addition, most polymers are highly flammable due to their chemical structure and organic composition. The challenges faced by polymer materials in terms of mechanical properties and flame retardancy have greatly limited their wide application.

【Achievement Introduction】

Recently, Associate Professor Shi Yongqian of Fuzhou University published a study titled "Interface engineering of MXene towards super-tough and strong polymer nanocomposites with high ductility and excellent fire safety" in the Chemical Engineering Journal, a high-impact journal in the field of materials launched by Elsevier Publishing Group Associate Professor Shi Yongqian is the first author of this paper, and Dr. Yu Bin, a postdoctoral fellow at the University of Southern Queensland, and Associate Professor Song Pingping are co-corresponding authors. The thesis reported that melamine cyanate (MCA) was loaded on titanium carbide nanosheets (Ti3C2Tx, MXene) by hydrogen bonding to prepare multifunctional nano-hybrid Ti3C2Tx@MCA and thermoplastic polyurethane (TPU)/Ti3C2Tx@MCA Nanocomposites. The experimental results show that the tensile strength, elongation and toughness of TPU/Ti3C2Tx@MCA-3.0 reached 61.5 MPa, 588.4% and 175.4 MJ m-3, respectively, and the peak heat release rate was reduced by 40.0% compared with TPU. The mechanical properties and flame retardant properties of the prepared TPU nanocomposites are obviously better than the similar samples in the past. The interfacial hydrogen bonding combined with the "labyrinth" effect and catalysis of two-dimensional Ti3C2Tx nanosheets is the main reason for achieving excellent mechanical properties and flame retardant properties of TPU nanocomposites. This work provides a new strategy for designing high-performance polymer materials with a combination of excellent mechanical properties and flame retardant properties.

【Graphic introduction】

Figure 1. (a) Synthesis of Ti3C2TX@MCA nano-hybrid; (c) Preparation of TPU/Ti3C2Tx@MCA nanocomposite; (b) Digital photo of (nano) additive dispersion: (b-1) Ti3C2Tx@MCA Dispersed in deionized water, (b-2) MCA dispersed in DMSO, (b-3) Ti3C2Tx@MCA dispersed in DMSO.

Figure 2. (a) XRD patterns of Ti3AlC2, Ti3C2TX, MCA and Ti3C2TX@MCA; (b) FTIR patterns; (c) TGA curve under nitrogen; (d) XPS graph; (e) MCA and Ti3C2Tx@MCA high N 1S XPS image at resolution; (f) Side view of the structure of a single-layer Ti3C2TX nanosheet loaded with MCA.

Figure 3. SEM images (a) Ti3AlC2, (b) Ti3C2Tx, (e) MCA and (f, g) Ti3C2Tx@MCA; (h) EDX image of Ti3C2Tx@MCA (c) AFM image of Ti3C2Tx nanosheet and its corresponding Height curve (d)

The etched and stripped Ti3C2TX layer spacing is larger than that of untreated Ti3AlC2, and the Ti3C2Tx after MCA is loaded, the layer spacing further increases significantly. For MCA, the absorption band at 3390 cm-1 in FTIR is attributed to the stretching vibration of NH2, and the stretching vibration of NH2 shifts to a stronger peak number (3405 cm-1) after Ti3C2Tx is loaded with MCA, indicating NH2 in MCA /NH forms a hydrogen bond with the hydroxyl group in Ti3C2Tx. For the Ti3C2Tx@MCA nanohybrid, the binding energy at the 1s level in the nitrogen element increases significantly due to the decrease in electron density around the nitrogen atom or the formation of hydrogen bonds. The SEM image of the Ti3C2Tx@MCA nanohybrid exhibits an irregular distribution similar to graphene-like nanosheets. This is because after loading MCA molecules, the interlayer coupling is weak, which improves the dispersion of the Ti3C2Tx nanosheets and prevents Their stacking. The EDX diagram shows that a part of the Ti3C2Tx@MCA nano-hybrid is mainly composed of Ti, C, and O elements, while another part of the region is mainly composed of Ti, C, O, and N elements. The above results indicate that MCA was successfully loaded on Ti3C2Tx nanosheets and exhibited excellent dispersibility.

Figure 4. Mechanical properties of TPU and its nanocomposites

Figure 5. (a) TPU/Ti3C2Tx@MCA-3.0 freeze cracked surface and (b, c) TPU/Ti3C2Tx@MCA-3.0 tensile fracture surface SEM image; (d) schematic drawing of the tensile process model.

By limiting the fluidity of polymer chains, hydrogen bonding improves the mechanical properties of TPU nanocomposites: the tensile strength, elongation and toughness of TPU/Ti3C2Tx@MCA-3.0 nanocomposites increased by 47.5% and 5.4 respectively compared to TPU % And 56%. For all SEM images of (nano) composite materials, in addition to tearing characteristics, it is easy to observe a large number of network structures caused by hydrogen bonding interactions, and the tensile cross-section of TPU/Ti3C2Tx@MCA-3.0 shows approximately compact The flat shape does not have any agglomeration, which further shows that Ti3C2Tx@MCA is evenly dispersed in the TPU.

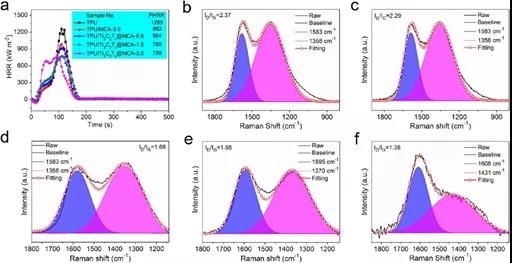

Figure 6. (a) HRR curves of TPU, TPU/MCA and TPU/Ti3C2Tx@MCA nanocomposites; (b) TPU, (c) TPU/MCA-3.0, (d) TPU/Ti3C2Tx@MCA-0.5, ( e) Residual carbon Raman spectra of TPU/Ti3C2Tx@MCA-1.5 and (f) TPU/Ti3C2Tx@MCA-3.0.

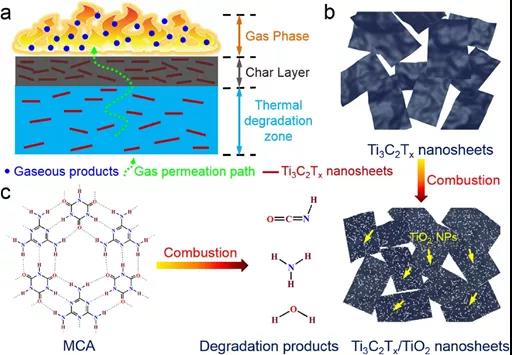

Figure 7. (a) TPU/Ti3C2Tx@MCA nanocomposite flame retardant model description; (b) Ti3C2Tx nanosheet combustion conversion; (c) MCA degradation after combustion.

The peak heat release rate (PHRR) of TPU/Ti3C2Tx@MCA-0.5, TPU/Ti3C2Tx@MCA-1.5, TPU/Ti3C2Tx@MCA-3.0 decreased by 28.5%, 37.9% and 40.0% respectively compared with TPU, and TPU nanocomposites The ID/IG values are lower than TPU, indicating that the carbonization degree of TPU nanocomposites is higher than that of TPU. The SEM image of TPU carbon slag showed porous and loose morphology. With the increase of Ti3C2Tx@MCA addition, the morphology of carbon slag was improved. The carbon slag of TPU/Ti3C2Tx@MCA-3.0 showed a continuous and dense state, and no large-scale holes were found. The excellent flame retardant properties of these TPU nanocomposites benefit from the solid phase and gas phase flame retardant effects of Ti3C2Tx@MCA: Ti3C2Tx passes through the barrier effect of nanosheets and the catalytic effect of TiO2 on the surface and edges of Ti3C2Tx during the solid phase, thereby preventing The bottom polymer material is heated to promote the production of a protective carbon layer; MCA first decomposes into various gaseous compounds, including NH3, H2O, and HNCO, and finally evolves into a carbon-nitrogen polymer. In addition, the resulting polymer carbon nitride is thermally degraded into non-flammable nitrides at high temperatures, such as C3N2, C1N4, C3N3, and so on. These non-flammable nitrides can dilute the concentration of combustible gas products and oxygen generated during the TPU combustion process, thereby further improving the flame retardant performance of the composite material.

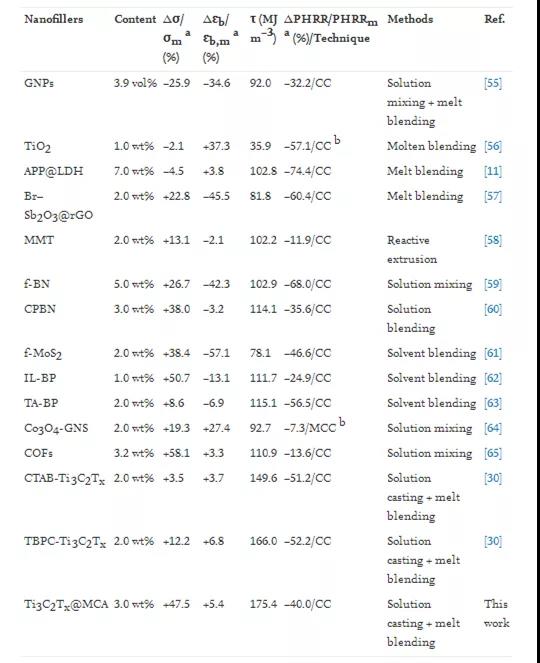

Table 1. Comparison of mechanical properties and combustion properties of TPU/Ti3C2Tx@MCA and typical TPU nanocomposites.

As can be seen from Table 1, Ti3C2Tx@MCA nanocomposites are superior to other TPU nanocomposites in terms of comprehensive mechanical properties and flame retardant properties.

【Summary of this article】

In this study, the surface of Ti3C2Tx was modified by supramolecular assembly technology, and the multifunctional nano-hybrid material Ti3C2Tx@MCA was successfully prepared and characterized. Then, it was combined with TPU to prepare nanocomposites. Due to the strong interface interaction, Ti3C2Tx@MCA is well dispersed in the TPU matrix. Compared with TPU, the PHRR of TPU/Ti3C2Tx@MCA-3.0 nanocomposite is reduced by 40%, the tensile strength and elongation have reached 61.5 MPa and 588.4%, respectively. The mechanical properties and flame retardant properties show obvious advantages. The strong interfacial interaction between the well-dispersed Ti3C2Tx@MCA and the TPU matrix promotes load transfer, matrix deformation and fracture energy dissipation during stretching through dynamic hydrogen bonding, thereby improving the strength and toughness of the composite. This work provides an innovative method for designing high-performance polymer nanocomposites with excellent mechanical properties and fire safety properties.

The work was published in Chemical Engineering Journal

(DOI:10.1016/j.cej.2020.125829

Full text link: https://doi.org/10.1016/j.cej.2020.125829

Source: MXene Frontier

This information originates from the Internet for academic exchange only. If there is infringement, please contact us to delete

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |