ACS NANO: Reasonable design of sulfur-doped three-dimensional Ti3C2Tx MXene/ZnS heterostructure multifunctional non-dendritic zinc ion battery protective layer

QQ Academic Group: 1092348845

Detailed

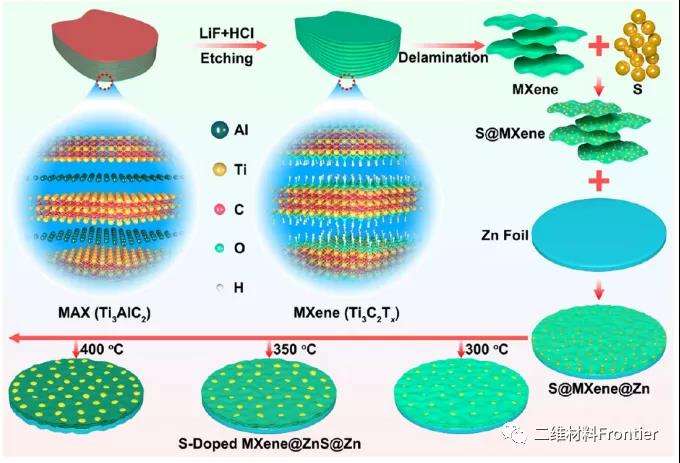

1. Article overview

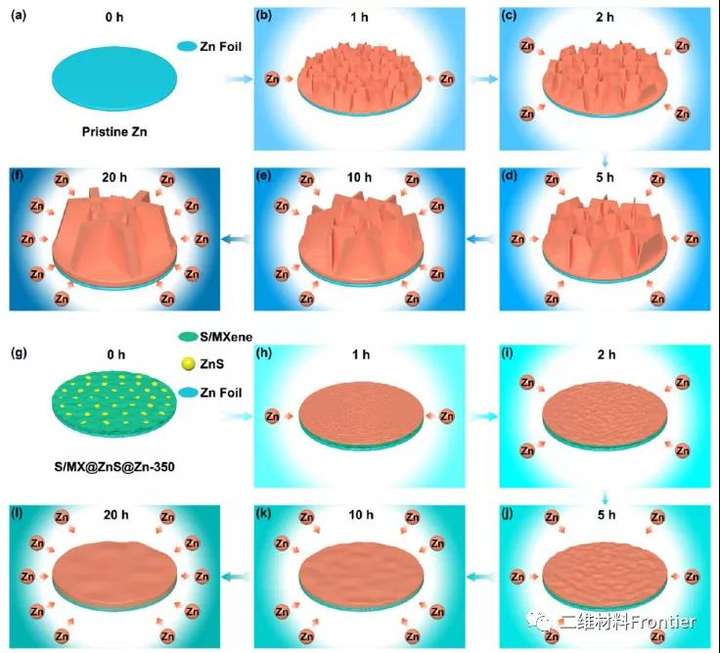

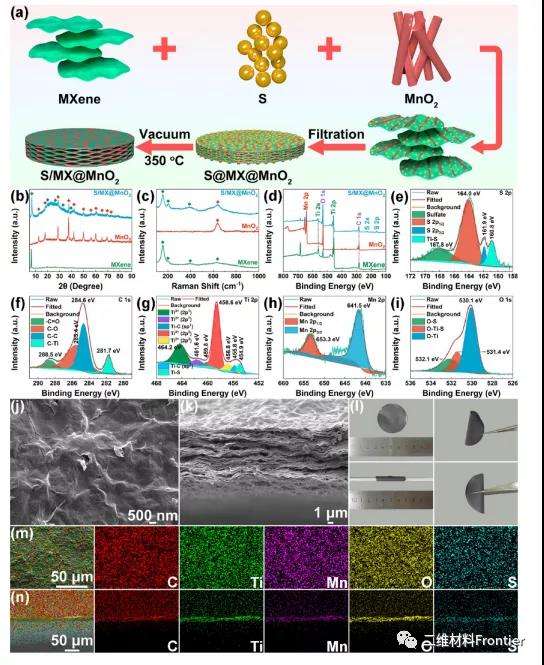

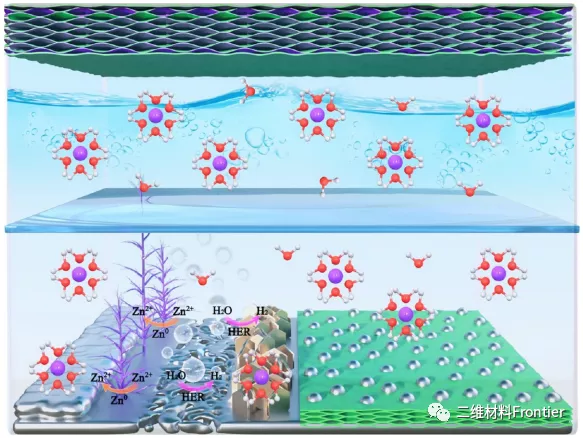

Zinc metal has the advantages of large theoretical capacity, great working potential, abundant resources, intrinsic safety, and low cost. It is considered to be one of the most promising anode materials for water batteries. However, the harm caused by dendrite growth and side reactions hinders its practical application. Aiming at the above problems, a Zn anode heterogeneous protective layer composed of electronically conductive sulfur-doped three-dimensional MXene and ion-conductive ZnS was designed and constructed. Sulfur doping and the formation of three-dimensional structures on MXene are simultaneously achieved during the ZnS generation process. Sulfur-doped 3D MXene can effectively uniform electric field distribution, reduce local current density, and ease volume changes. ZnS can inhibit side reactions, promote the uniform distribution of Zn2+, and accelerate the migration of Zn2+. Therefore, a stable non-dendritic zinc anode is obtained, with obvious cycle stability up to 1600 h and rate performance. The relationship between the structure of the protective layer and the performance of the zinc anode was discussed. The protective zinc anode and the 3D MXene@MnO2 cathode doped with suspended sulfur can be used to obtain a full battery with high energy, long cycle life and high rate. This work provides direction for the design of practical zinc anode and other metal-based battery systems.

3. Full text summary

In summary, a heterogeneous protective layer composed of electronically conductive sulfur-doped 3D MXene and ion-conductive ZnS is designed. The advantages of this layer can be summarized as (1) the simultaneous realization of sulfur doping and ZnS generation. (2) Sulfur-doped 3D MXene can effectively guide the uniformity of Zn electrodeposition by homogenizing the electric field distribution, reducing local current density and alleviating volume changes. (3) ZnS can promote the uniform distribution of Zn2+, accelerate the migration of Zn2+, and inhibit side reactions (passivation, corrosion, hydrogen evolution, etc.). (4) The protection interface has high stability in the ZnSO4 aqueous solution. By avoiding side reactions caused by the electrolyte and adjusting the electroplating/stripping behavior of Zn, the reversibility of the Zn anode is enhanced. Under the action of these synergistic effects, the zinc anode has significant rate performance and cycle stability of more than 1600 h. The relationship between the structure of the protective layer and the performance of the zinc anode is discussed. The high-rate, stable and flexible full battery also constructs an independent sulfur-doped MXene@ MnO2 cathode. This work provides ideas for the development of zinc metal anodes and other metal-based battery systems. This work can also guide the interface engineering of zinc metal anodes and other metal-based battery systems.

Article link:

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

- Previous: Science: Biocompatible

- Next: A Rising 2D Star: Nove

Academic Frontier

Academic Frontier