一、文章概述

With the development of terahertz (THz) technology, there is an increasing demand for terahertz shielding/absorbing materials to avoid electromagnetic interference (EMI) or pollution. The coating can be quickly cured to form a film, and can be stably attached to any substrate, which is particularly suitable for shielding/absorption applications. In recent years, due to its good electronic conductivity and hydrophilicity, MXenes has attracted widespread attention in the field of electromagnetic interference shielding. Here, we show a kind of MXene water-based paint (MWP) based on copolymerized acrylic latex (PAL), which not only has strong terahertz electromagnetic interference shielding/absorption efficiency, but also can be easily adhered to various commonly used Terahertz substrate. The viscosity of MWP can be adjusted by adjusting the colloidal force and viscous force, and the cyano group in PAL provides a strong intermolecular polar interaction between MWP and the substrate. The results show that the MWP thickness of the quartz surface is 38.3 μm, the EMI shielding value is 64.9 dB, and the reflection loss of the coated sponge foam is 32.8 dB. This substrate-independent MWP provides a simple and effective method for achieving high-performance terahertz shielding/absorption.

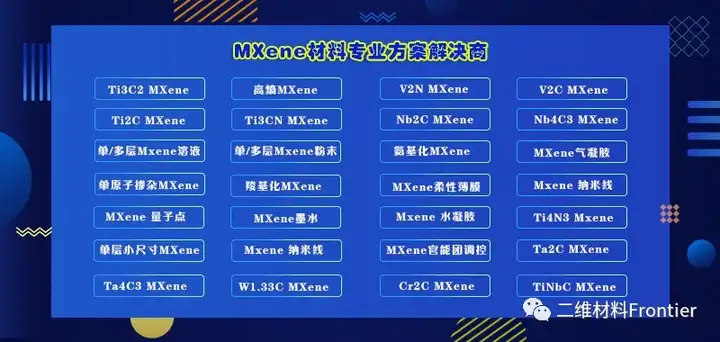

Figure 1 shows the synthesis of MWP and the determination of the viscosity of MWP with different filling amounts. (a) Schematic diagram of the preparation of Ti3C2Tx water dispersion and Ti3C2Tx MXene water-based paint. (b) Viscosity of 40 mg/mL MXene water dispersion and MWP of different filler content.

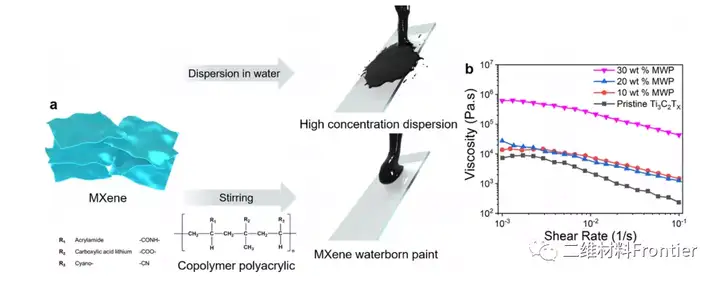

Figure 2. Characterization of Ti3C2Tx and MWP. (a c) Schematic diagram of the main contribution changes of different MXene filler content to viscosity. (d) SEM image of Ti3C2Tx flakes on alumina filter. (e) XRD spectra of Ti3C2Tx and MWP with different filler content. The original MXene has a strong (002) peak at 6.1, corresponding to the interlayer spacing of 1.45 nm. When the mass fraction of MXene is 10 wt%, the (002) diffraction peak shifts from 6.1 to 5.0, and when the mass fraction of MXene is 20 wt%, the diffraction peak shifts from 5.68 to 5.86. (f) The XPS spectrum of n1s is 30 wt% MWP. (g) Compare the adhesion stability of MXene and MWP after ultrasonic treatment in ethanol for 5 min. The image on the left shows MXene and 30 wt% MWP coated quartz placed in 50 mL ethanol. (h) Ultraviolet-visible spectra of MXene and MWP (30wt% MXene) after 5min ultrasonic treatment. The absorbance of MWP-quartz ultrasonic solution is about 0.006%, which is much lower than pure mxene-quartz ultrasonic solution and reference solution.

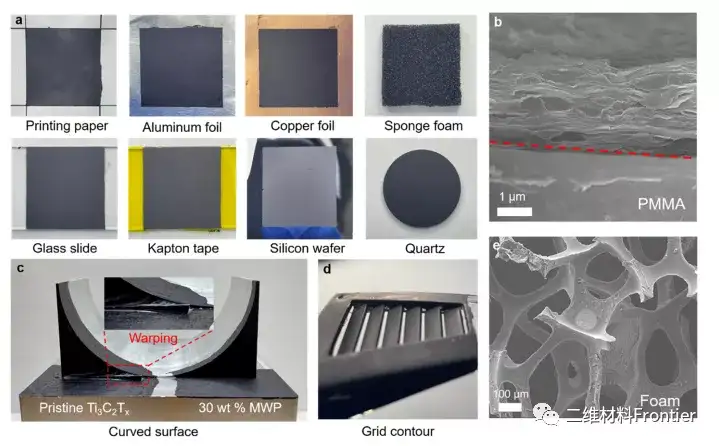

Figure 3. MWP coatings on various substrates. (a) Photos of 30 wt% MWP coating on different substrates: printing paper, aluminum foil, copper foil, sponge foam, glass slide, Kapton tape, silicon wafer and quartz. (b) The SEM image of 30 wt% MWP adhered to the PMMA substrate shows that the MWP layer structure is preserved under the shear stress of the doctor blade coating. (c) A comparison photo of pure MXene and MWP vs. irregular shape aluminum alloy. The inset shows the warped MXene film at the corners of the irregular aluminum alloy. (d) The photos of some complex structures taking the MWP coating (PMMA) on the grid outline as an example. (e) The SEM image of 30 wt% MWP coating on the sponge foam. It can be seen that there are many MXene films on the sponge foam skeleton.

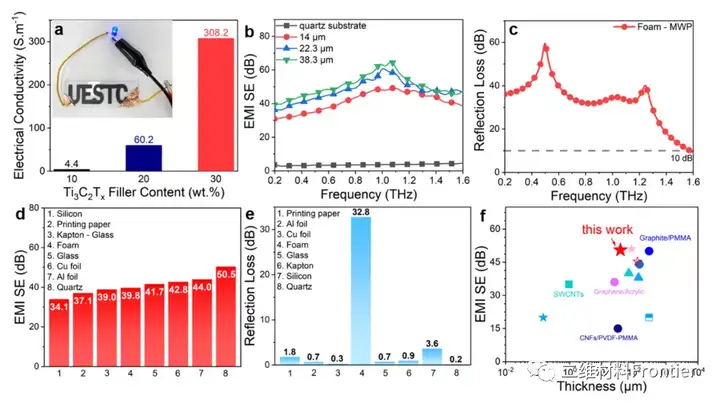

Figure 4. Electrical conductivity of MWP and terahertz radiation shielding/absorption performance of 30 wt% MWP. (a) The electrical conductivity of different Ti3C2Tx filler content MWP. (b) The relationship between EMI SE and 30 wt% MWP of quartz thickness. (c) RL value of MWP painted sponge foam. (d) 30 wt% MWP coated EMI SE with different types of substrates: flexible, rigid, and porous. (e) RL of different types of substrates: flexible, rigid, and porous. (f) Comparison of EMI SE with previous literature. Each symbol represents a group of material categories, as shown below: MWP (red star), Ti3C2Tx sponge foam (pink star), Ti3C2Tx composite hydrogel (red open star), graphite/PMMA (sea blue filled circle), PAN/ TPU composite material (sea blue filled circle), CNW-PMC composite material (copper green filled triangle), SWCNTs (copper green filled square), graphene/acrylic (lilac filled circle), MWCNTs/PEEK (sky blue filled triangle) , Ti3C2Tx coating metamaterial (sky blue star), CNFs/PVDF-PMMA (indigo filled circle), SWCNTs/PVA (sky blue half filled square).

3. Full text summary

In summary, the author proposes a general method that can effectively transform different substrates into excellent terahertz EMI shielding/absorbing substrates. When traditional EMI shielding materials are coated on various substrates, their interaction with the surface of the substrate is limited, which limits their wide application. A high-viscosity, high-adhesion, fast film-forming MXene water-based coating was prepared by using the copolymer PAL containing high polarity-C triN functional group, and its broadband terahertz electromagnetic interference absorption was demonstrated on various shapes of substrates. And shielding performance. The presence of various functional groups in the copolymer adjusts the viscosity of the MXene suspension by adjusting the colloidal force and viscosity. At the same time, the -C triN group of PAL provides a strong intermolecular polar interaction between the MWP and the substrate. Highly filled polymers are composed of conductive fillers, and highly polar groups can be a general strategy to overcome poor wettability and insufficient bonding interactions between most EMI coatings and substrates. Therefore, this work aims to provide a promising alternative to miniaturized electronics for 6G communications and EMI absorption and shielding on the most irregular device surfaces that need to eliminate terahertz radiation.

Article link:

https://doi.org/10.1021/acsnano.1c04656

一、文章概述

一、文章概述

Academic Frontier

Academic Frontier