Roadmap of massive nanomaterials based on 2D building blocks

QQ Academic Group: 1092348845

Detailed

| It is well known that two-dimensional (2D) materials such as graphene and molybdenum disulfide (MoS 2 ) have unique properties. A family of 2D structures with multiple chemistry can open the door to better understanding of the performance differences between 2D and 3D materials. Leads to identifying useful properties of two-dimensional carbides, nitrides, oxycarbides, and other related structures; and ultimately leads to new applications. | |

| A recent study ( "2D, Ordered, Double Transition Metal Cemented Carbide (MXenes)" ) shows that 2D material families, especially MXenes ( read more about MXenes in our previous Nanowerk Spotlight ) Can be based on the new "dual metal" strategy. | |

| With the complementarity of these 2D systems with other nanostructures, it is now possible to use a variety of well-defined nanostructure materials, so that researchers can focus more on scaling up the synthesis of these nanoscale building blocks, and in bulk form Do not study them as a single unit. | |

| In a wider range of materials science and engineering background, this expansion of nanomaterials is ACS Nano ( : "bulk nanostructured materials based on two-dimensional components of the road map" in the) subject of a Perspective article, the author in this An assembly roadmap was constructed here to transform nanoscale building blocks into bulk nanostructured materials and define some key challenges and goals. | |

| As the author writes, 2D drawings are a great fit for this roadmap for building dense, large-sized samples with scalable material properties or interesting emerging characteristics. But no matter what kind of structure is used, "when using nanostructures in bulk form with superior material properties, it is vital that these extraordinary nanoscale properties can be scaled to the macro level." | |

| A good example is the challenge of scaling up the performance of carbon nanotubes (CNTs) to the macro scale. Materials engineers are passionate about taking advantage of the excellent mechanical properties of carbon nanotubes for use in fibers, composites, fabrics, and other large structures and equipment through future applications (such as space elevators) . The ability to make continuous multifunctional yarns represents an important step in this direction (more information: " Spinning multi-kilometer multi-layer carbon nanotube yarns "). | |

|

|

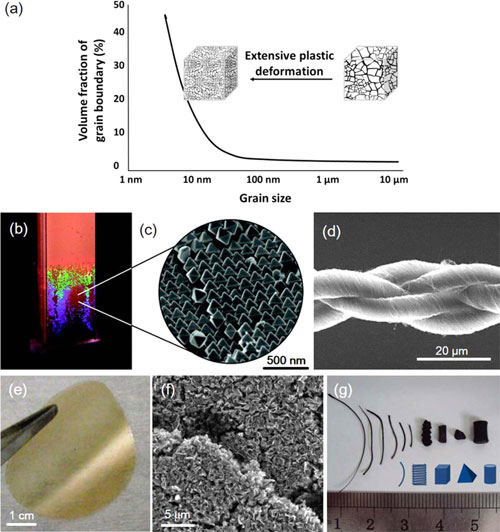

| The bulk form of nanomaterials: top-down and bottom-up. (A) It was initially shown that bulk nanostructured materials are made of metal processed through a large number of plastic deformations, which greatly reduces their grain size, which leads to abnormal mechanical properties. This curve illustrates the general trend of increasing grain boundary volume fraction and decreasing grain size. On the other hand, discrete nanoscale entities are often assembled into blocks to create new properties or use in applications. Some examples include the following: (b) Plasma colloidal crystals with vivid colors that can be tuned by (c) the assembly of octahedral Ag nanocrystals (© American Chemical Society). (D) Carbon nanotube twisted yarn with extraordinary strength and toughness (© American Association for the Advancement of Science). (E) A layered film made of exfoliated clay flakes with unipolar ion migration and high ion conductivity (© Nature Publishing Group). (F) Granulated powder of wrinkled graphene balls with a scalable surface area. (G) Dense nanoporous graphene monolith 19, which has a moldable shape and excellent supercapacitor performance (© Nature Publishing Group). (Click on the picture to enlarge) | |

| With regard to defining a roadmap for new bulk nanostructured materials for bottom-up assembly, the authors point out that there are many challenges that can be summarized as scalability and stability . | |

| "Scalability refers to both the scalable synthesis of high-quality processible nano-scale structural blocks and the scalable material properties in which the properties of nano-scale units can still be obtained in the final bulk part. Their stability is also important because they should not be sintered into large particles or chemically converted to less useful materials during processing or use. " | |

|

|

| The roadmap shows a bottom-up assembly path towards new bulk nanostructured materials, highlighting scalability and stability challenges. (Reprinted with permission from the American Chemical Society) | |

|

The authors concluded that two-dimensional materials are probably the most promising, used to define bulk nanostructured engineering materials and well-defined nano-scale building blocks: "Two-dimensional sheets can form close face-to-face contact, and They bend, wrinkle, or wrinkle. During assembly, some even plastically deform at the single-layer level, so they can build high-density bulk samples with adjustable free volume and porosity. In terms of stability If the material of the mother layer is thermodynamically stable, then we may expect the exfoliated 2D sheet to have sintering resistance and maintain its single-layer or several-layer thickness. However, compared with bulk materials, their high surface area is Leading to higher chemical reactivity, which should be addressed for the target application. Proper packaging or surface passivation can alleviate this problem without sacrificing performance. " Source: Nanowerk |

- Previous: Wrinkled graphene ball

- Next: What is graphene?

Application

Application