hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

Carbon nanotubes with good performance and wide application

Carbon nanotube (CNT) is a coaxial nanotube composed of carbon atoms arranged in a hexagonal shape. As a one-dimensional quantum material, it has attracted wide attention due to its many special mechanical, electrical and chemical properties. CNT has high flexibility, aspect ratio>1000, elastic modulus close to 1000 GPa, strength about 100 GPa, electrical conductivity and thermal conductivity as high as 1800 s·cm-1 and 3000 W·m-1·K-1, respectively. Such excellent performance makes CNT an ideal nanofiller for composite materials, which is widely used in the fields of fibers, films, sensors, electronic products, additive manufacturing and energy storage equipment.

The precise arrangement of CNT is a problem

As we all know, the microstructure of composite materials determines performance. As far as CNT composite materials are concerned, the distribution position, dispersion effect and nano-scale alignment of CNTs have significant effects on their performance. Due to the strong interaction of CNTs, and the often crimping and twisting when synthesizing CNTs, it is difficult to achieve dispersion and accurate arrangement of CNTs in the current mainstream methods.

Simple and crude "violence aesthetics"

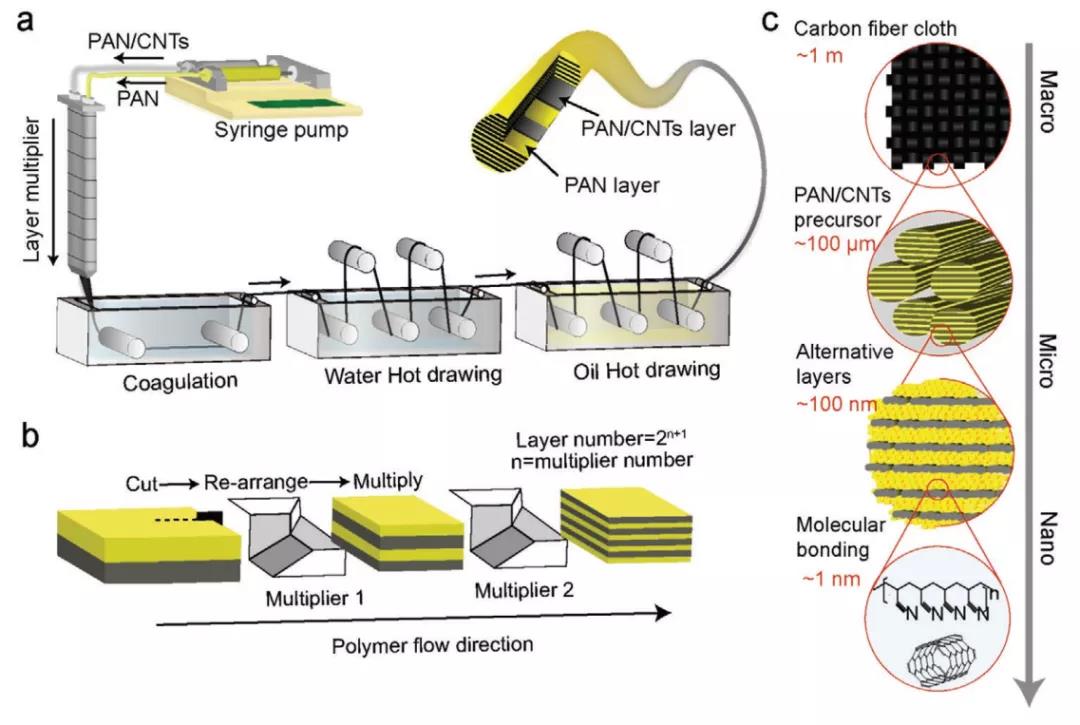

The research group of Professor Kenan Song of Arizona State University proposed a dry-blown-wet spinning, forced self-assembly composite fiber preparation method, and prepared highly oriented, alternately assembled polyacrylonitrile (PAN) and PAN/CNT nano-layer structure fibers .

The general idea of Professor Kenan Song can be described as "violent aesthetics", which is to continuously cut the polymer solution-and then layer, similar to the fission process of cells. They first introduced two polymer solutions of PAN and CNT/PAN into a specially designed layerer. The solution was cut into two strands in the horizontal direction, and then the two strands were layered in the vertical direction. Thus, a single layerer can convert two strands of raw materials into four layers, and they used eight layerers to prepare 512 layers of optical fiber with a layer spacing of 170 nm. This simple and crude method successfully solves the problem of CNT dispersion while dispersing the solution to a nanometer thickness, and as the area between layers increases, the shear stress increases, and it is easy to realize the orientation of CNTs on the nanometer scale. . The fiber prepared in this way is not only beautiful in structure, but also significantly improved in performance: Compared with the CNT/PAN fiber prepared by the traditional method, the modulus of the layered fiber is increased by 27.4%, and the strength is increased by 22.2%. Compared with the pure PAN fiber, The modulus is increased by 46.4%, while the strength is increased by 39.5%.

The more layers, the better the dispersion quality of CNT

image

Figure 1. Characterization of multilayer fiber structure.

In this fiber preparation method, the thickness of the thin layer and the viscosity matching between the layers are the key factors. The researchers found that the zero-shear viscosity increased significantly with the increase of the number of layers, from 46.43 for 8 layers to 68.70 Pa·s for 128 layers, while the viscosity of the PAN/CNT solution without stratification was only 49.33 Pa·s. The increase may be due to the non-smooth interface between PAN and CNT/PAN layer.

Under the microscope, the layer spacing of 8, 32, 256, and 512 layers of fibers are respectively 9, 3.5, 0.37 and 0.17 μm. The layer spacing of the 1024 layer structure is not obvious, which is due to the lack of high resolution of the 3D printed layerer. . The sizes of CNT aggregates in 8, 32, 256, and 512 layers of fibers are 6.9, 5.6, 5.1, 4.2 μm2, respectively. When it is increased to 1024 layers, the CNT size increases to 6.9 μm2 instead. It shows that the CNT dispersion effect is the best in the 512-layer fiber structure.

The more layers, the better the fiber strength

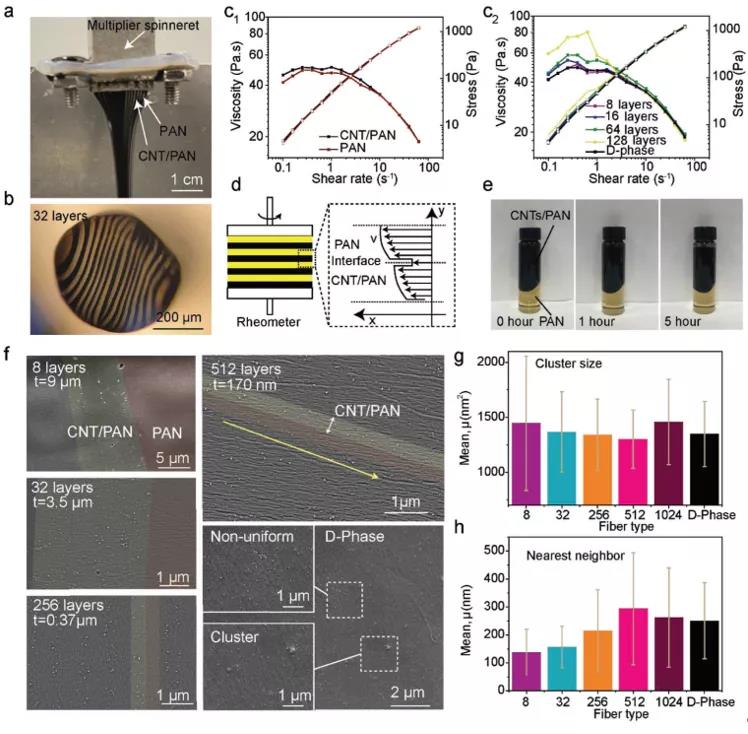

Figure 2. Fiber mechanical properties.

Compared with pure PAN fiber, when 0.5% CNT is added, the ultimate tensile strength and Youngs modulus of non-layered PAN/CNT fiber increase by 12.3% and 12.9%, respectively. Subsequently, the researchers compared the mechanical properties of PAN/CNT fibers with different layers and found that when the number of layers is 16, 32, and 64, the mechanical properties of the fibers are slightly increased compared to 8 layers, when the number of layers reaches 128 layers. Later, the fiber Youngs modulus and ultimate tensile strength increased significantly, and reached the highest values of 19.3 and 689 MPa at 512 layers. By constructing this nano-level PAN and PAN/CNT alternating structure fiber, compared with PAN fiber, the modulus and strength of the 512-layer fiber are increased by 46.4% and 39.5%. Even compared with the non-layered PAN/CNT fiber, the modulus and strength are increased by 27.4% and 22.2%.

The balance of strength and toughness has always been the goal pursued by material researchers. The toughness and strength of pure PAN fibers are 26.67 MJ·m-3 and 494.41 MPa, respectively. With the increase in the number of composite fiber layers, the toughness and strength of the 512-layer fibers reached 36.37 MJ·m-3 and 689.54 MPa, respectively, an increase of 39.5% and 36.4%, which are inseparable from the good dispersion of CNTs.

The more layers, the better the performance

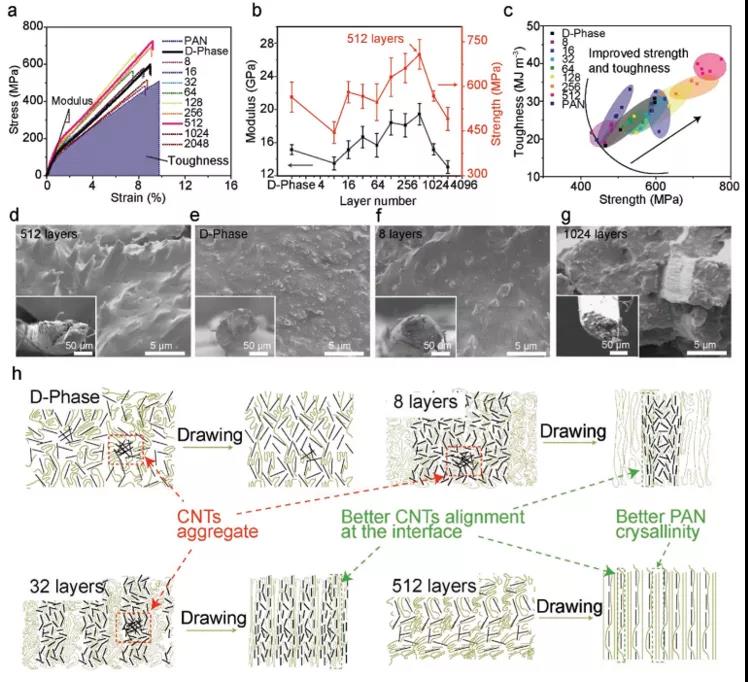

Figure 3. Dynamic mechanical analysis.

In order to study the reason why the more layers have better performance, the researchers conducted research from two aspects: interlayer shear and CNT orientation.

They first performed a dynamic mechanical analysis of the fiber to study the interaction between layers. It is found that the loss tangent tan(δ)c value of the composite fiber at room temperature decreases with the increase of the number of layers, and the value of the 512-layer fiber is the lowest. This is the reason for its high elasticity, indicating that the activity of the polymer chain is restricted. The loss tangent tan(δ)in value at the fiber interface of the 512 layers is the largest, indicating that the energy dissipation at the interface between the CNT and PAN segments is high. This is due to the large boundary area between the PAN/CNT and PAN layers. When the temperature exceeds the Tg of PAN, the difference in viscoelastic behavior between PAN and CNT/PAN causes the polymer chain to elongate, resulting in strong shear stress at the interface of each layer, so the interface energy consumption is high.

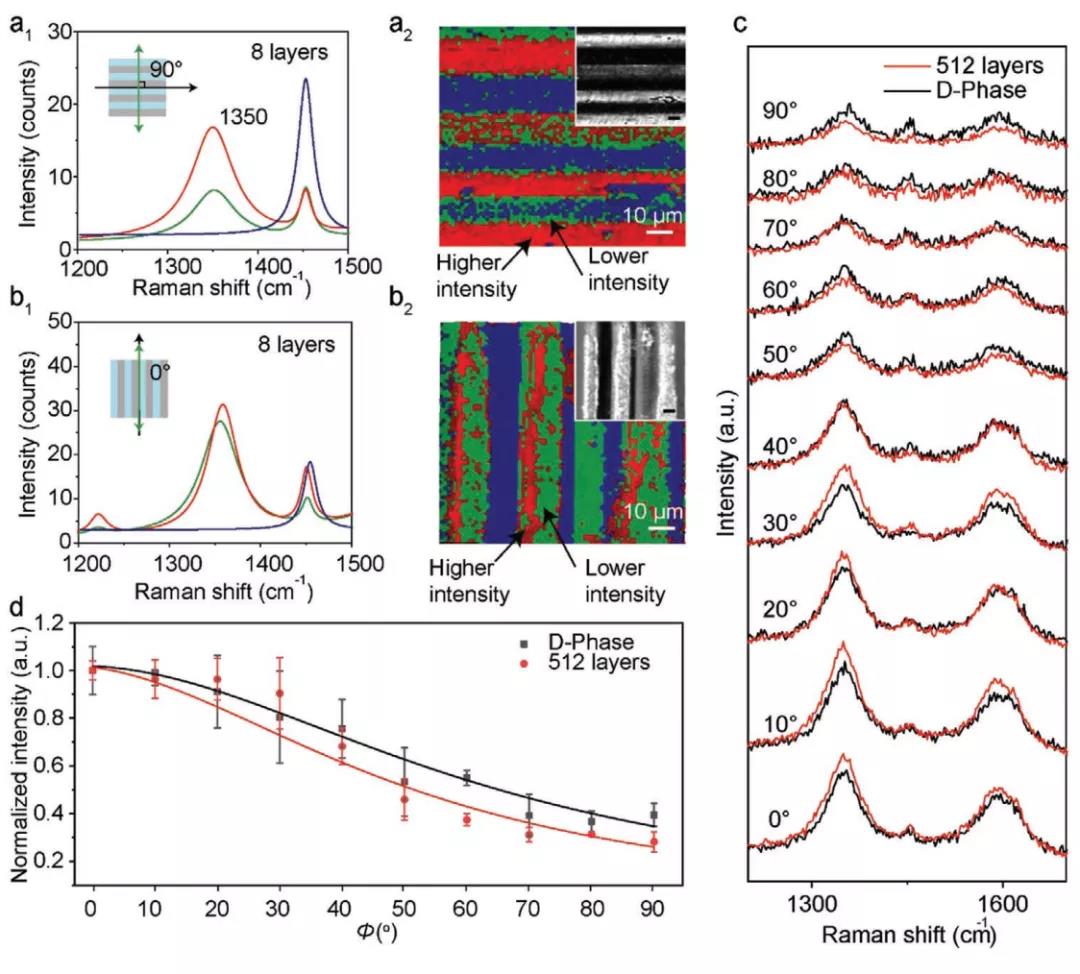

Figure 4. Polarized Raman spectroscopy analysis.

Interfacial shear can often lead to the orientation of CNTs. Subsequently, the researchers used polarized Raman spectroscopy to study the alignment of CNTs. When the Raman beam is incident perpendicular to the fiber direction, due to the polarization effect, a "VV"-shaped pattern appears. As the non-orientation angle between the beam and the fiber decreases, the "VV" intensity increases and becomes parallel to the fiber direction. The peak strength is the largest.

When the incident light is parallel to the fiber, the signal intensity at the edge of the CNT/PAN layer is higher than that in the middle, indicating that the CNT has formed a better orientation along the axial direction of the fiber at this position. This is because as the number of layers increases, The increase of the interlayer area and the greater shear stress lead to the orientation and arrangement of CNTs. Among the 512-layer fibers, the ratio of I0°/I90° reached 3.57, which was much higher than the 2.56 of the non-layered mixed fiber, which also indicated the higher the orientation of CNTs along the axial direction.

Summary: In order to solve the problem of poor dispersion of CNTs in the polymer and low degree of orientation, the researchers proposed a dry jet-wet spinning, forced self-assembly composite fiber preparation method, which was prepared in a simple and crude manner. Highly oriented PAN and PAN/CNT nano-layer structure fiber. When eight layerers are used, 512 layers of fibers are prepared with a layer spacing of 170 nm, which realizes the nano-dispersion of CNTs in the polymer, and uses the significantly increased shear stress between the layers to achieve the CNT at the interface. orientation. Compared with CNT/PAN fibers prepared by traditional methods, the strength and toughness of the fibers are significantly improved.

Original link:

https://onlinelibrary.wiley.com/doi/10.1002/adfm.202009311

Source of this article: Frontiers of Polymer Science

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |